From precision components in mobile phones to crankshafts in automotive engines, the smooth surfaces and precise dimensions of these parts all rely on a key technology—grinding processing. This article provides a comprehensive introduction to the applications of grinding, types of grinding machines, types of grinding wheels, and selection methods, helping readers systematically understand this technology.

1. Grinding Processing: A Versatile Method for Both Hard and Soft Materials

The application range of grinding processing is extremely wide. It can handle cylindrical surfaces (internal and external), conical surfaces, flat surfaces, as well as complex formed and combined surfaces.

Its advantages are mainly reflected in the following aspects:

Excellent finishing capability: Most parts requiring high surface precision rely on grinding in the final stage;

Strong capability for hard materials: For hardened parts or high-hardness special materials (such as cemented carbide), ordinary cutting tools are ineffective, while grinding can efficiently process them;

Adaptable to roughing: Grinding is not only used for finishing but can also handle roughing tasks, ensuring production efficiency.

2. Grinding Machine Family: Equipment with Specialized Functions

Grinding processing relies on grinding machines as key equipment. Different types of machines are suited to different processing objects and requirements:

-External cylindrical grinder: Used for external cylindrical surfaces of parts, such as shafts;

-Internal cylindrical grinder: Used for internal cylindrical surfaces of parts, such as sleeves;

-Surface grinder: Mainly used for flat surfaces, ensuring surface flatness and precision;

-Specialized/customized grinding machines: Designed for specific parts (such as cutting tool edges, crankshafts, splines, gears), capable of processing complex formed or irregular surfaces for specialized production.

3. Grinding Wheel Selection: Five Key Factors Determining Processing Performance

The grinding wheel is the core tool of grinding, and its performance directly affects processing quality. A grinding wheel is composed of abrasive grains and a bonding material, and is manufactured through pressing, drying, firing, and dressing. The following five factors should be considered when selecting a grinding wheel:

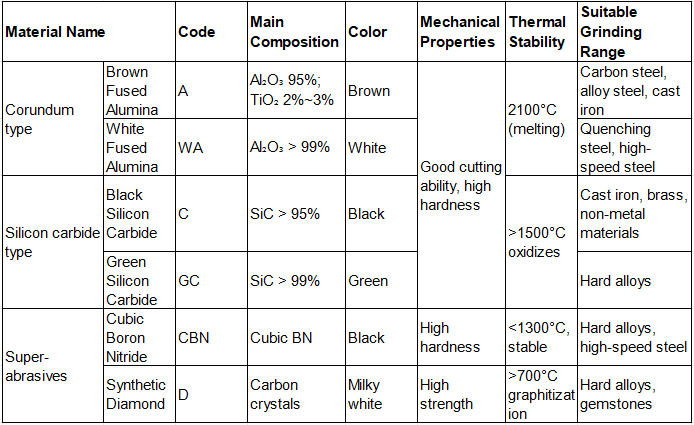

① Abrasive: The main cutting component of the wheel, equivalent to the “teeth”;

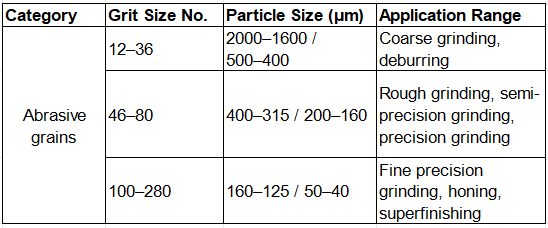

② Grain size: The size of the abrasive grains; finer grains produce smoother surfaces;

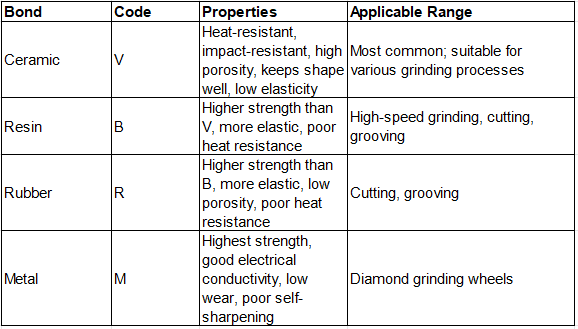

③ Bonding material: Holds the abrasive grains in place, affecting wheel strength, toughness, and durability;

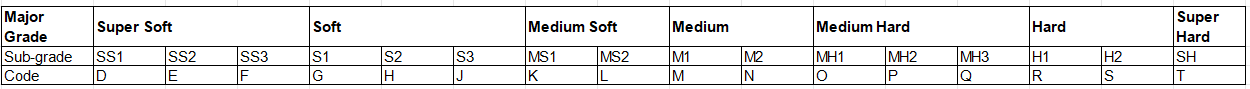

④ Hardness: The ease with which abrasive grains detach. Soft wheels are used for hard materials (grains detach easily to avoid scratching the workpiece), and hard wheels are used for soft materials;

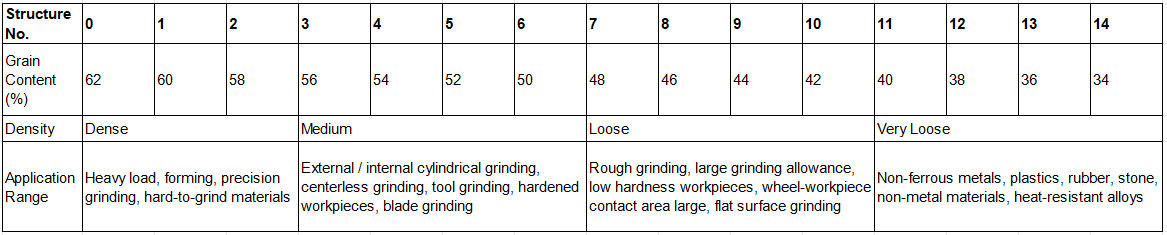

⑤ Structure: The internal porosity of the wheel. Large pores facilitate heat dissipation and chip removal, suitable for roughing; small pores improve precision, suitable for finishing.

4. Grinding Methods: Choosing the Right Approach to Improve Efficiency and Precision

Different workpieces require different grinding methods. Selecting the appropriate method helps improve efficiency and ensure precision.

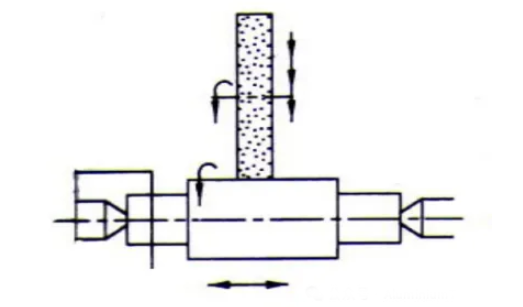

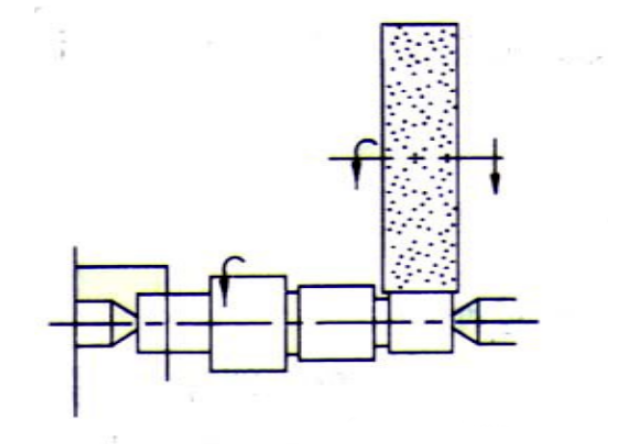

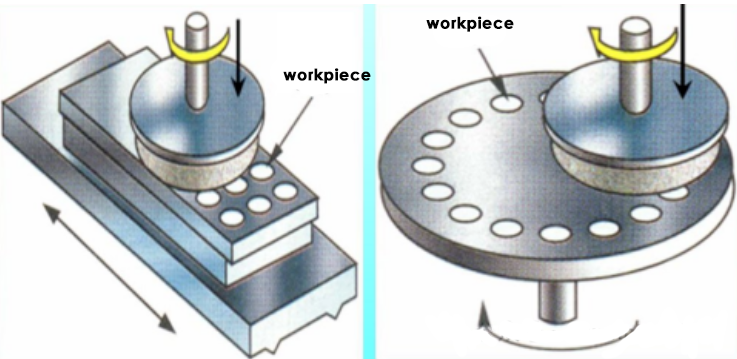

External/Internal Cylindrical Grinding:

Longitudinal feed grinding: High precision and excellent surface quality, suitable for high-precision parts;

Traverse feed grinding: High efficiency, suitable for batch production of short shafts or sleeves;

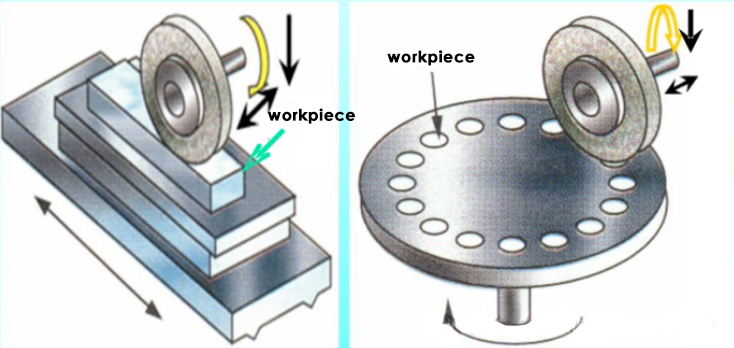

Surface Grinding:

Peripheral grinding: Using the side of the wheel to grind the surface, high precision, smooth surface, suitable for high-precision flat surfaces;

Face grinding: Using the face of the wheel to grind the surface, high efficiency, suitable for large-area flat surfaces.

Post time: Nov-22-2025