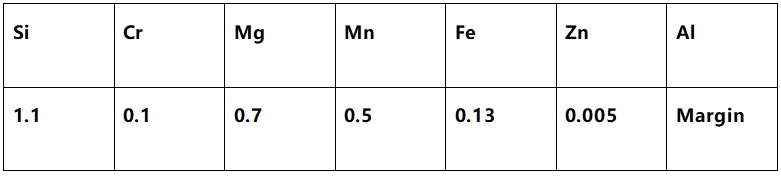

1. Alloy composition

2. Homogenization Process

390℃ x insulation for 1.0h + 575℃ x insulation for 8h, strong wind cooling to 200℃ and then water cooling.

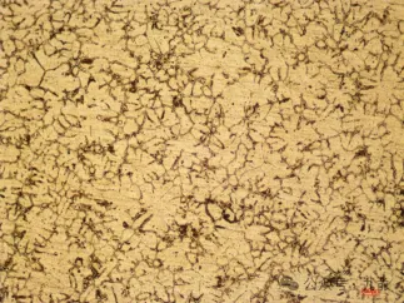

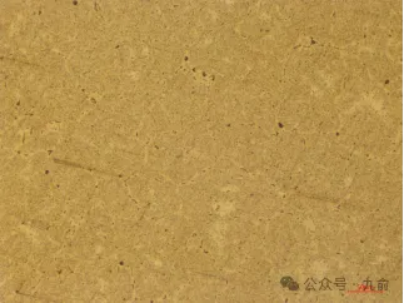

3. Metallographic Structure

Figure 1 Metallographic structure of the core of 6082 alloy ingot, etched by Keller reagent, with well-developed dendrites

Figure 2 Metallographic structure of the core of 6082 alloy ingot, etched by Keller reagent, and structure after solid solution

4. Effect of homogenization heat treatment on alloy structure

4.1 As shown in Figure 1, the alloy has well-developed dendrites in the cast state, and there are a large number of network non-equilibrium precipitation phases at the grain boundaries.

4.2 Since the melting points of different elements are different when the alloy solidifies, this sequential solidification phenomenon leads to uneven solute composition within the crystal, which is specifically manifested in the generation of a large number of network precipitation phases at the grain boundaries.

4.3 In the microstructure after homogenization treatment (Figure 2), the amount of precipitated phases at the grain boundaries is greatly reduced, and the grain size increases synchronously. This is because the diffusion of atoms is enhanced under high temperature, segregation elimination and non-equilibrium phase dissolution occur in the ingot, and the network compounds on the grain boundaries are partially dissolved.

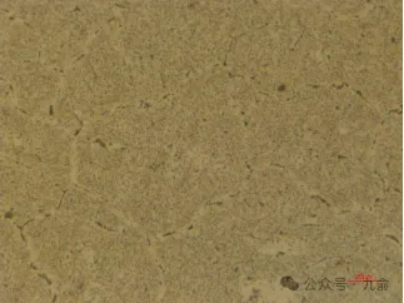

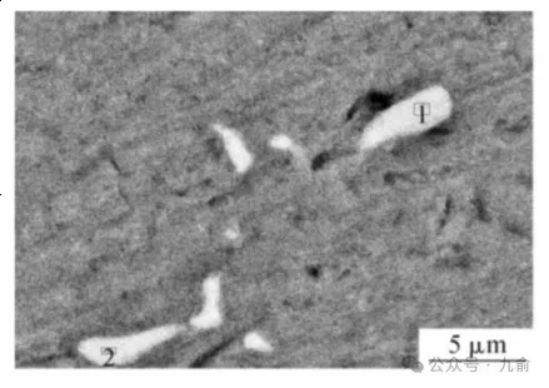

4.4 Through SEM analysis, as shown in FIG3 , different parts of the precipitated phase were selected for EDS analysis, confirming that the precipitated phase was Al(MnFe)Si phase.

4.5 During alloy casting, a large amount of Mn-containing precipitation phase is formed, and a part of it is retained in the supersaturated solid solution. After high-temperature and long-term homogenization treatment, the Mn supersaturated in the matrix precipitates in the form of Mn-containing compounds, which is manifested as a large number of dispersed Mn-containing compound decomposition particles precipitated in the crystal (Figure 2).

4.6 Since the precipitated phase contains Mn element, it has good thermal stability. With the intensification of atomic diffusion, the Al(MnFe)Si phase particles gradually show spheroidization characteristics.

Fig.3 Al(MnFe)Si phase in 6082 alloy

5. Effect of solution aging system on mechanical properties

After homogenization, the network precipitated phase originally at the grain boundary of 6082 alloy is dissolved, which can improve the comprehensive mechanical properties of the sample. At the same time, the stable heat-resistant phase Al(MnFe)Si phase is further spheroidized, which can better pin dislocations. This shows that the comprehensive performance of the material will be improved after homogenization heat treatment.

6. Conclusion

6.1 The 6082 aluminum alloy ingot has well-developed dendrites and a large number of network non-equilibrium precipitation phases at the grain boundaries.

6.2 After homogenization treatment, microscopic observation revealed that the amount of precipitated phases was greatly reduced, and the grain size increased synchronously. Segregation elimination and non-equilibrium phase dissolution occurred in the ingot, and the network compounds on the grain boundaries were partially dissolved.

6.3 When casting 6082 alloy, Al(MnFe)Si precipitation phase is generated. This precipitation phase contains Mn element and has good thermal stability. As the homogenization process proceeds, the precipitation phase particles gradually show spheroidization characteristics. This Mn-containing compound particles are uniformly dispersed and precipitated in the crystal.

6.4 After homogenization treatment, the dissolution of the network precipitated phase indicates that the overall performance of the entire ingot is improved after homogenization heat treatment.

Post time: Jun-08-2025