I. Introduction

Aluminum is a metal widely used in various fields, featuring light weight, high strength, corrosion resistance, and recyclability. With the large-scale production and use of aluminum products, the amount of waste aluminum generated continues to increase. Waste aluminum recycling not only reduces dependence on primary aluminum resources, lowers energy consumption and environmental pollution, but also brings considerable economic benefits to enterprises. In the waste aluminum recycling process, smelting is a key step, and the application of the double-chamber furnace provides strong support for improving recycling efficiency and quality.

II. Forms of Waste Aluminum Recycling

2.1 Social Recycling

Social recycling mainly comes from various discarded aluminum products in daily life, such as beverage cans, aluminum doors and windows, aluminum pots, aluminum basins, etc. This type of waste aluminum is widely distributed and sourced in a scattered manner, making recycling relatively difficult. It is usually collected by individual recyclers and recycling stations, then transported to large waste aluminum recycling enterprises. Socially recycled waste aluminum is diverse in type and has high impurity content, requiring strict classification and pretreatment.

2.2 Industrial Recycling

Industrial recycling mainly comes from aluminum processing enterprises, machinery manufacturing companies, and automobile manufacturers, in the form of scraps and waste produced during processing. Industrial waste aluminum is characterized by centralized sources, stable quality, and lower impurity content, making it easier to recycle. Enterprises usually cooperate with fixed recycling companies to promptly recycle the waste aluminum generated during production, achieving resource circulation.

III. Constraints of Aluminum Yield on Production Costs

Aluminum yield refers to the ratio, expressed as a percentage, between the weight of qualified aluminum products obtained after smelting and the weight of the waste aluminum input. The yield directly affects production costs and economic benefits.

3.1 Factors Affecting Yield

Waste aluminum quality: The type, impurity content, and surface treatment of waste aluminum all affect yield. Waste aluminum with high impurity content requires more impurity removal operations during smelting, increasing aluminum loss and reducing yield. Waste aluminum with paint, plating, and other coatings requires pretreatment, and losses may occur during this process.

Smelting equipment and processes: Different equipment and processes significantly affect yield. Traditional smelting equipment has low energy efficiency and high metal oxidation loss, resulting in lower yield. Advanced equipment such as double-chamber furnaces uses advanced combustion technology, waste heat recovery, and aluminum liquid circulation systems to effectively reduce metal loss and improve yield.

3.2 Impact of Yield on Costs

Raw material cost: When yield is low, more waste aluminum must be input to obtain the same amount of qualified product, increasing procurement costs.

Energy cost: Lower yield means more energy is required for smelting and impurity treatment, increasing energy costs.

Other costs: Low yield may also increase the consumption of fluxes, refining agents, as well as maintenance and labor costs.

IV. Structure and Working Principle of the Double-Chamber Furnace

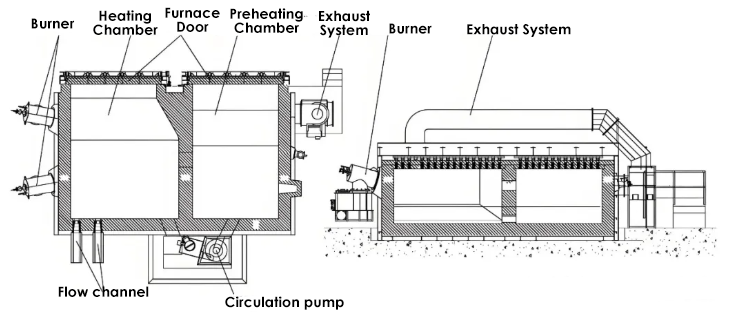

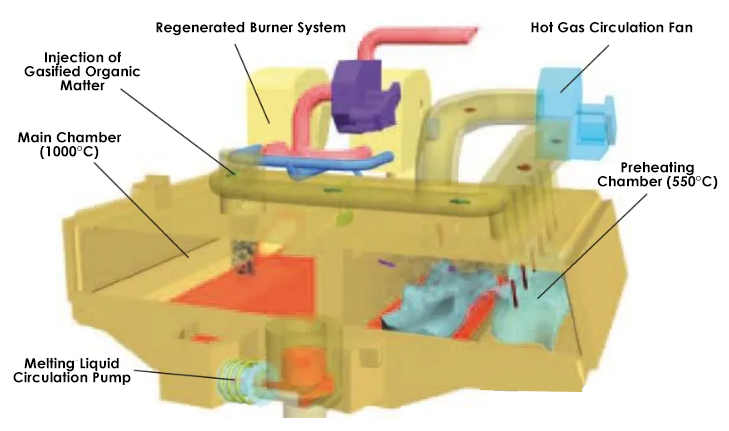

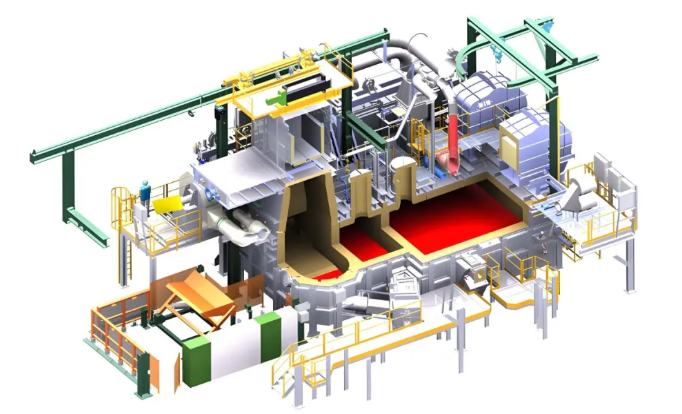

4.1 Structure

Heating chamber: The heating chamber provides the main heat source. Two main burners on one sidewall maintain the temperature within the set range, typically around 1050°C, providing melting conditions for clean raw materials such as aluminum ingots. A charging bridge is installed at the furnace door for clean materials.

Scrap chamber: Used for melting heavily contaminated waste aluminum. It is separated from the heating chamber by a wall with upper and lower channels for flue gas and aluminum liquid. A wide charging bridge is installed at the furnace door for various waste aluminum. A flue gas recirculation fan and auxiliary burner are installed near the charging bridge. The fan uses hot flue gas to preheat waste on the bridge and sends part of the flue gas to the heating chamber.

Aluminum liquid circulation system: Consists of an electromagnetic pump well, scrap chamber melt pool, and heating chamber melt pool. The electromagnetic pump drives aluminum liquid from the heating chamber to the scrap chamber, raising its temperature and melting waste. Aluminum liquid then returns through the wall channels. The pump well structure forms a vortex, allowing aluminum chips, magnesium, silicon, and small scrap to be added.

Central heat exchanger: Consists of two chambers containing honeycomb ceramic regenerator bodies and switching valves. It alternates between exhaust and supplying hot combustion air. High-temperature flue gas enters and rapidly cools at 1500°C/s, preventing the recombination of NOx and dioxins.

Combustion system: Uses regenerative combustion. High-temperature flue gas heats combustion air to about 900°C before entering the burners.

Control system: Connects all subsystems and controls smelting temperature, flue gas temperature, aluminum liquid circulation, hot air circulation, furnace pressure, furnace atmosphere, emissions, safety interlocks, and emergency states.

Charging system: Equipped with a dedicated charging vehicle. Charging time is short (less than 15 minutes per batch), with high efficiency (3–4 tons per batch). The furnace door, charging vehicle, and dust hood form a sealed connection to prevent flue gas leakage.

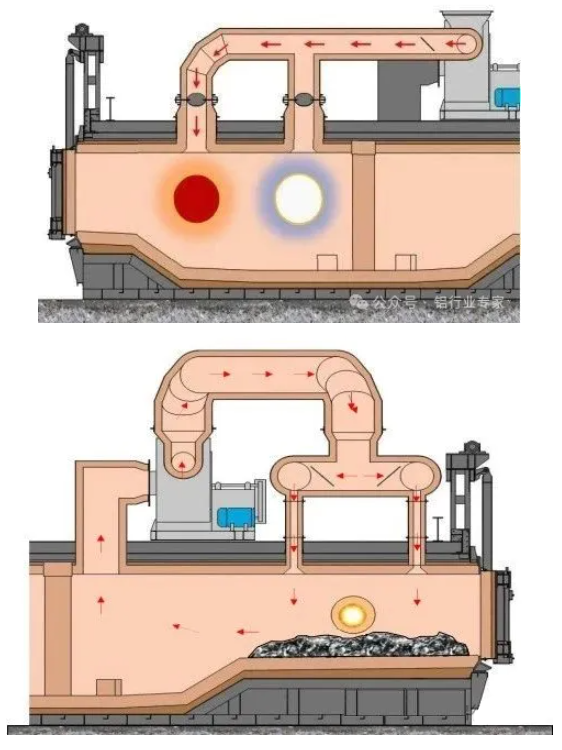

4.2 Working Principle

During operation, the heating chamber maintains high temperature via the main burners, rapidly heating clean materials. The scrap chamber receives waste aluminum. The flue gas recirculation fan preheats scrap on the charging bridge. The auxiliary burner provides heat when necessary. High-temperature aluminum liquid is pumped from the heating chamber to the scrap chamber, melting the waste. It then flows back to the heating chamber, completing circulation. Flue gas containing pyrolysis gases from the scrap chamber is sent to the heating chamber and completely combusted at over 1000°C. The central heat exchanger recovers waste heat and preheats combustion air, improving efficiency. The control system ensures stable and efficient operation.

V. Functions of the Double-Chamber Furnace

5.1 Efficient Melting of Waste Aluminum

The unique structure and working principle enable efficient melting of all types of waste aluminum, whether high-impurity social scrap or relatively clean industrial scrap. Aluminum liquid circulation and flue gas circulation ensure efficient heat use and shorten melting time.

5.2 Reduction of Metal Oxidation Loss

Atmosphere control keeps oxygen levels at 2–5%, far below typical levels, reducing oxidation. The scrap chamber operates in a reducing atmosphere, preventing oxidation. Aluminum liquid circulation ensures uniform temperature, avoiding local overheating. The vortex formed in the pump well quickly submerges material, reducing oxidation. Maintaining a melt pool allows preheated material to melt quickly, minimizing contact with flame and furnace gas.

5.3 Energy Saving

Waste heat recovery heats combustion air to 900°C and lowers exhaust temperature to 190–230°C. Aluminum liquid circulation prevents overheating. Pyrolysis gases undergo secondary combustion, reducing fuel consumption. Sealed charging prevents heat loss. Automatic control stabilizes temperatures and improves energy utilization.

5.4 Environmental Protection

Proper furnace design, temperature control, and waste gas treatment ensure pollutants such as NOx and dioxins are decomposed. Rapid cooling prevents recombination. Dust removal systems ensure emissions are below national standards.

VI. Role of the Double-Chamber Furnace in Waste Aluminum Recycling

6.1 Improving Recycling Efficiency

Traditional equipment melts slowly and has low efficiency. The double-chamber furnace, with its advanced structure and heating design, enables fast melting and continuous production. Large charging amounts and short charging time greatly improve capacity. For example, some enterprises achieve daily output of 150 tons per furnace, a 40% improvement over traditional equipment.

6.2 Improving Recycling Quality

The double-chamber furnace reduces metal loss and improves aluminum liquid purity and stability. Precise control of atmosphere and temperature, along with circulation and mixing, ensures uniform composition. Aluminum alloy ingots produced can achieve over 97% metal recovery and 30% improvement in uniformity, meeting high-end requirements such as aerospace and automotive applications.

6.3 Reducing Production Costs

Energy-saving features reduce natural gas consumption to less than 65 m³ per ton of aluminum at 720°C, reaching international advanced levels and reducing energy use by 20–30% compared with traditional furnaces. Higher yield reduces raw material needs. Lower oxidation loss further reduces waste. Long service life and low maintenance cost also reduce operating expenses.

6.4 Promoting Environmental Sustainability

With stringent environmental requirements, the double-chamber furnace helps enterprises reduce emissions. NOx can be controlled below 50 mg/m³, meeting ultra-low emission standards. Dust emissions remain far below national limits, greatly improving environmental performance.

VII. Advantages of the Double-Chamber Furnace

7.1 Comparison with Traditional Single-Chamber Furnaces

Metal loss: Single-chamber furnaces melt all scrap in one chamber and have oxidation loss as high as 20% for thin scrap. The double-chamber furnace reduces oxidation via structural design and atmosphere control, achieving recovery rates above 97%.

Energy use: Traditional furnaces have low efficiency and large heat loss. The double-chamber furnace recovers nearly 100% of waste heat and heats combustion air to 900°C, reducing specific energy consumption to less than 65 m³ per ton, saving 20–30%.

Production efficiency: Single-chamber furnaces have unstable temperatures and low efficiency. The double-chamber furnace enables continuous feeding and fast melting, shortening cycle time to 8 hours and increasing capacity by 40%.

7.2 Adaptability to Various Waste Aluminum Materials

The double-chamber furnace handles diverse materials including oily scrap and coated scrap. The scrap chamber and flue gas circulation allow pretreatment and decomposition of impurities. For example, automotive dismantling scrap can be melted directly without complex pretreatment.

VIII. Future Development Trends

8.1 Intelligent Upgrading

With the development of AI and IoT, future double-chamber furnaces will collect and analyze more operating data and automatically adjust parameters. Machine learning can optimize combustion strategies. Remote monitoring and fault diagnosis will reduce downtime.

8.2 Integration with Renewable Energy

To meet carbon peak and neutrality goals, future systems may integrate solar, wind, or biomass energy to reduce fossil fuel dependence. Energy storage may help stabilize power supply.

8.3 Miniaturization and Modular Design

Small and modular double-chamber furnaces will suit distributed recycling models, offering flexibility, low investment, and easy maintenance.

8.4 Deep Integration and Coordinated Development

Waste aluminum recycling will increasingly integrate smelting with sorting, refining, and casting. System-level collaboration will improve efficiency and quality. Collaboration among manufacturers, recyclers, and research institutions will promote innovation.

IX. Conclusion

The waste aluminum double-chamber furnace plays an irreplaceable role in waste aluminum recycling. Through its structure and working principle, it achieves efficient melting, reduced oxidation loss, energy savings, and environmental protection. Compared with traditional furnaces, it greatly improves efficiency, quality, cost-effectiveness, and sustainability. With continued technological development, double-chamber furnaces will evolve toward intelligence, renewable energy integration, miniaturization, modularization, and coordinated development, bringing new opportunities to the industry. Recycling enterprises should actively adopt such advanced technologies to enhance competitiveness and contribute to resource recycling and environmental protection.

Post time: Nov-22-2025