Extensive research has been conducted on the addition of rare earth elements (REEs) to 7xxx, 5xxx, and 2xxx series aluminum alloys, showing notable effects. In particular, 7xxx series aluminum alloys, which contain multiple alloying elements, often experience severe segregation during melting and casting, leading to the formation of significant amounts of eutectic phases. This reduces toughness and corrosion resistance, compromising the overall performance of the alloy. The incorporation of rare earth elements into highly alloyed aluminum alloys can refine grains, suppress segregation, and purify the matrix, thereby improving microstructure and overall properties.

Recently, a type of superplastic grain refiner has gained attention. These refiners exploit rare earth elements such as La and Ce to enhance the weakening of grain and subgrain boundaries. This not only refines grains but also promotes a uniform dispersion of precipitates, suppresses recrystallization, and significantly improves alloy ductility, ultimately increasing productivity in extrusion processes.

In 7xxx series aluminum alloys, rare earth elements are generally added in three ways:

1.Rare earth elements alone;

2.Combination of Zr and rare earth elements;

3.Combination of Zr, Cr, and rare earth elements.

The total content of rare earth elements is usually controlled within 0.1–0.5 wt%.

Mechanisms of Rare Earth Elements

Rare earth elements such as La, Ce, Sc, Er, Gd, and Y contribute to aluminum alloys through multiple mechanisms:

Grain refinement: Rare earth elements form uniformly distributed precipitates that act as heterogeneous nucleation sites, converting dendritic structures into equiaxed fine grains, which improves strength and ductility.

Suppression of segregation: During melting and solidification, rare earth elements promote more uniform element distribution, reduce eutectic formation, and increase matrix density.

Matrix purification: Y, La, and Ce can react with impurities in the melt (O, H, N, S) to form stable compounds, lowering gas content and inclusions, which enhances alloy quality.

Modification of recrystallization behavior: Certain rare earth elements can pin grain and subgrain boundaries, inhibiting dislocation motion and grain boundary migration. This delays recrystallization and preserves fine subgrain structures during thermal processing, improving both strength and corrosion resistance.

Key Rare Earth Elements and Their Effects

Scandium (Sc)

Sc has the smallest atomic radius among rare earth elements and is also a transition metal. It is highly effective in enhancing the properties of deformed aluminum alloys.

In aluminum alloys, Sc precipitates as coherent Al₃Sc, increasing the recrystallization temperature and suppressing grain coarsening.

When combined with Zr, high-temperature stable Al₃(Sc,Zr) particles form, promoting equiaxed fine grains and hindering dislocation motion and grain boundary migration. This improves strength, fatigue resistance, and stress-corrosion performance.

Excessive Sc may lead to coarse Al₃(Sc,Zr) particles, reducing recrystallization ability, strength, and ductility.

Erbium (Er)

Er acts similarly to Sc but is more cost-effective.

In 7xxx series alloys, appropriate Er additions refine grains, inhibit dislocation motion and grain boundary migration, suppress recrystallization, and enhance strength.

When co-added with Zr, Al₃(Er,Zr) particles form, which are more thermally stable than Al₃Er alone, providing better recrystallization suppression.

Excessive Er may produce Al₈Cu₄Er phases, reducing both strength and ductility.

Gadolinium (Gd)

Moderate Gd additions refine grains, increase strength and ductility, and enhance the solubility of Zn, Mg, and Cu in the matrix.

The resulting Al₃(Gd,Zr) phase pins dislocations and subgrain boundaries, suppressing recrystallization. An active film also forms on grain surfaces, further limiting grain growth.

Excessive Gd can cause grain coarsening and deteriorate mechanical properties.

Lanthanum (La), Cerium (Ce), and Yttrium (Y)

La refines grains, reduces oxygen content, and forms an active film on grain surfaces to inhibit growth.

La and Ce promote GP zone and η′ phase precipitation, improving matrix strength and corrosion resistance.

Y purifies the matrix, hinders the dissolution of major alloying elements into the solid solution, promotes nucleation, and reduces potential differences between grain boundaries and interiors, enhancing corrosion resistance.

Excessive La, Ce, or Y may lead to coarse blocky compounds, which reduce ductility and strength.

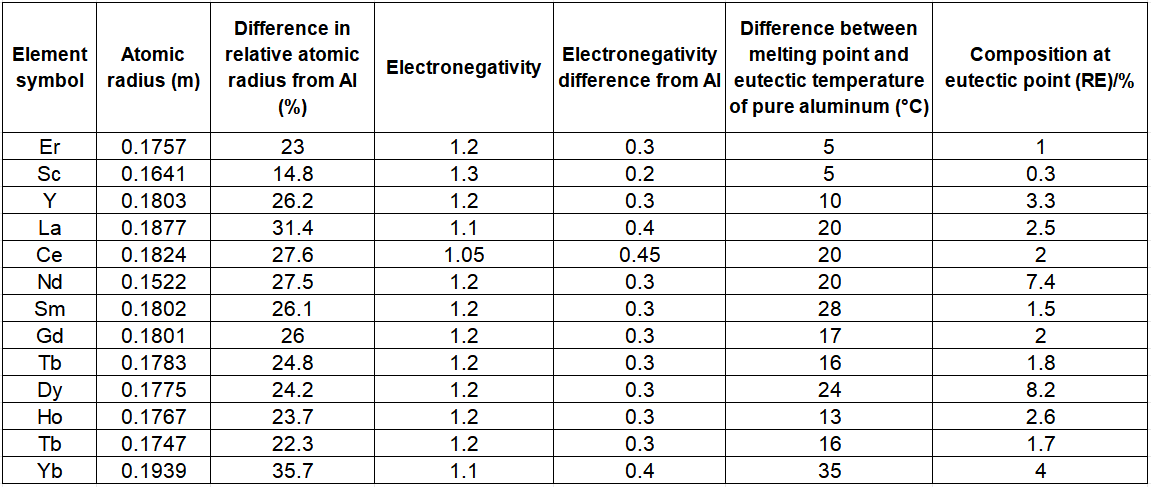

Properties of major rare earth elements and their characteristics in aluminum

Post time: Aug-21-2025