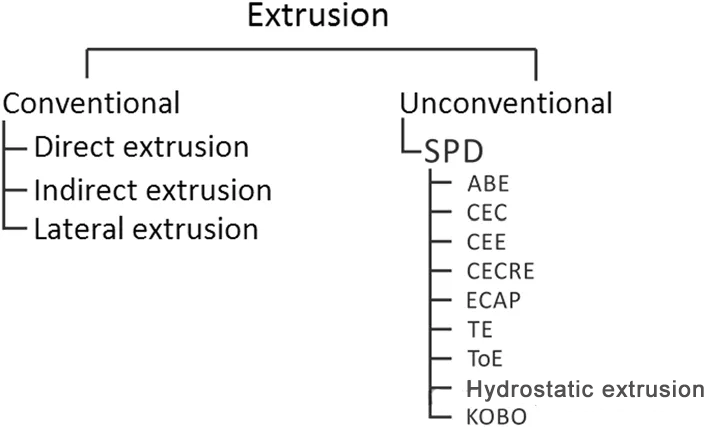

Extrusion is a widely used process for producing long metal and alloy profiles. It allows the manufacture of products with complex cross-sections, and even materials with limited deformability can be extruded into products with excellent mechanical properties and refined microstructures.

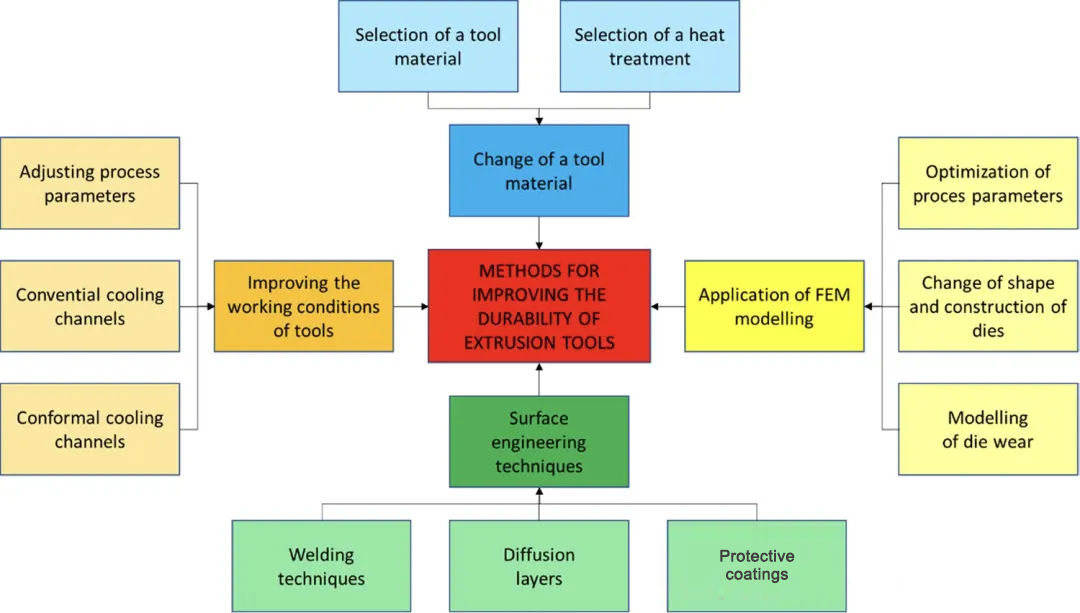

The microstructural changes that occur during the homogenization of heat-treatable aluminum alloy billets have long been a focus of research. Recent studies mainly concern the dissolution of soluble phases formed during solidification, the elimination of microsegregation, the precipitation of dispersoids, the transformation of insoluble phases, and the reprecipitation of particles during cooling. The design and working conditions of extrusion dies greatly influence product quality and tool life. With the help of computer-aided design (CAD), finite element method (FEM), and three-dimensional optical scanning, dimensional deviations of dies and extruded products can be analyzed with high precision.

In recent years, researchers have also explored various innovative extrusion methods, including severe plastic deformation (SPD) processes such as cyclic extrusion compression (CEC), equal-channel angular pressing (ECAP), and hydrostatic extrusion (HE). Furthermore, the novel KOBO extrusion process, which introduces oscillatory die motion, enables significant grain refinement and the consolidation of powder materials. Combining rapid solidification with hot extrusion can further improve microstructure and enhance mechanical performance.

In direct-chill (DC) cast billets, the dissolution of soluble phase particles and the elimination of microsegregation are regarded as the primary microstructural processes during homogenization heating and soaking. By the end of homogenization, elements participating in subsequent precipitation hardening should be maximally enriched in the (Al) solid solution. Effective utilization of alloying elements is fundamental to achieving the desired high strength in extruded products. Undissolved particles generally have a negative impact on fatigue resistance and fracture toughness.

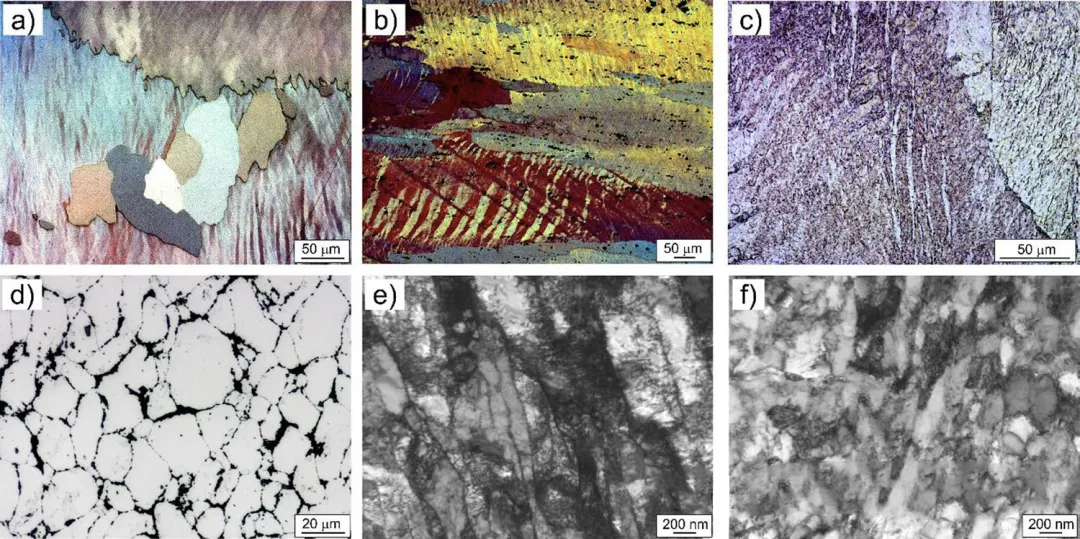

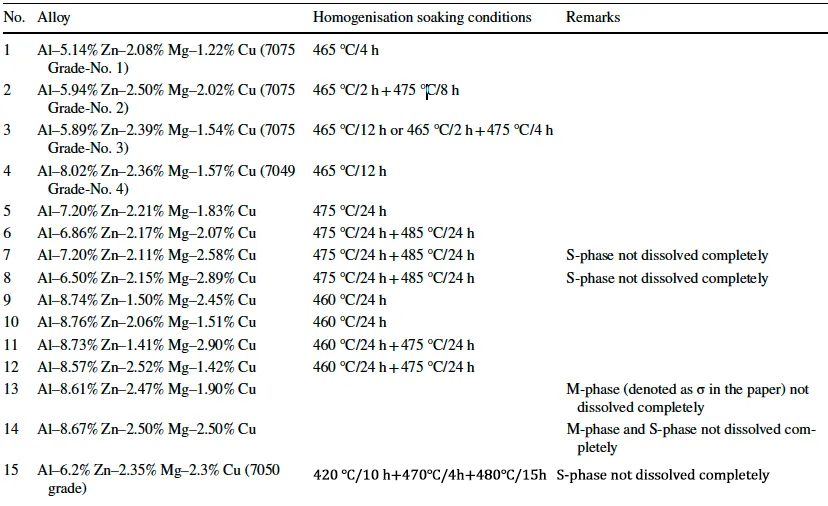

It is well known that the microstructure of high-strength aluminum alloy billets typically contains several soluble phases. For example, Al-Zn-Mg-Cu alloys may contain M-(Cu, Zn, Al)₂Mg, T-(Cu, Zn, Al)₄₉Mg₃₂, S-Al₂CuMg, β-Mg₂Si, Al₃Mg₂, and metastable Cu-rich phases [AlCuMgZn]. In Al-Mg-Si-Cu alloys, phases such as β-Mg₂Si, Q-Al₅Cu₂Mg₈Si₆, θ-Al₂Cu, and (Si) can appear. These complex microstructures lead to relatively low non-equilibrium solidus temperatures — approximately 460 °C for Al-Zn-Mg-Cu alloys and 485 °C for Al-Mg-Si-Cu alloys. To avoid incipient melting and ensure the dissolution of soluble phases, customized multi-stage homogenization schedules are typically required.

During homogenization, the precipitation of dispersoids from the solid solution significantly affects the microstructure and properties of high-strength aluminum alloys in subsequent processing. These dispersoids help control grain size and enhance fracture toughness. However, to achieve the desired effect, dispersoids must be fine and uniformly distributed. Microsegregation of alloying elements within dendrites and the low diffusivity of dispersoid-forming elements hinder this, prompting extensive research on optimized heat-treatment cycles to minimize the adverse effects of microsegregation.

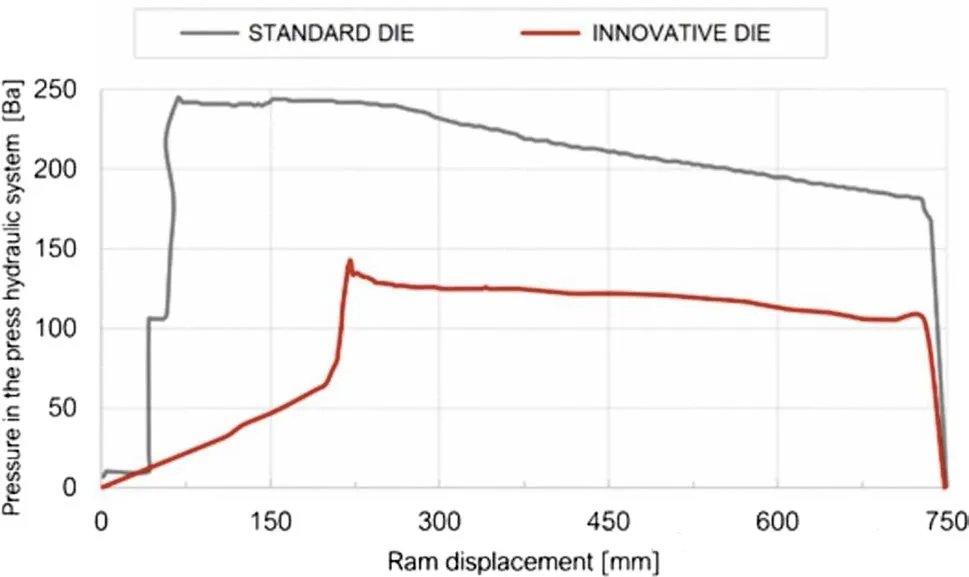

The adoption of low-pressure casting (LPC) technology has led to a reduced interdendritic segregation zone (ISZ) width and lower solute concentration within this region. This increases the solidus temperature significantly — for example, by more than 30 °C for the 6060 alloy — enabling higher homogenization temperatures (up to 600 °C). At such high temperatures, the transformation of β-AlFeSi to α-AlFeSi proceeds more completely, particularly in Mn-free alloys. Extrusion experiments have shown that the lack of Mn and the use of this new cooling method reduce the required extrusion pressure.

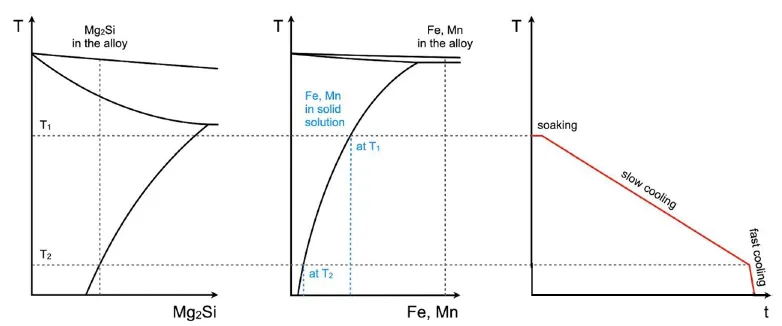

Cooling after homogenization strongly affects the extrudability of the billet and the properties of profiles after solution heat treatment. The β-Mg₂Si phase tends to precipitate as particles that can readily redissolve during subsequent processing. The solubility of Mn and Fe in (Al) is limited and decreases with temperature; therefore, slow cooling at high temperatures may cause Mn and Fe to precipitate and transform into AlFeSi particles. Phase diagrams indicate that, in 6xxx alloys, the dissolution temperatures of Fe and Mn are higher than that of β-Mg₂Si (see Fig. 2). Based on this, a new dual-rate cooling (DRC) schedule was developed: slow cooling between the soaking temperature (T₁) and the β-Mg₂Si dissolution temperature (T₂), followed by rapid cooling below T₂ to prevent the formation of coarse β-Mg₂Si particles. Extrusion tests showed that DRC typically reduces extrusion pressure by about 2–3%, a modest but consistent improvement.

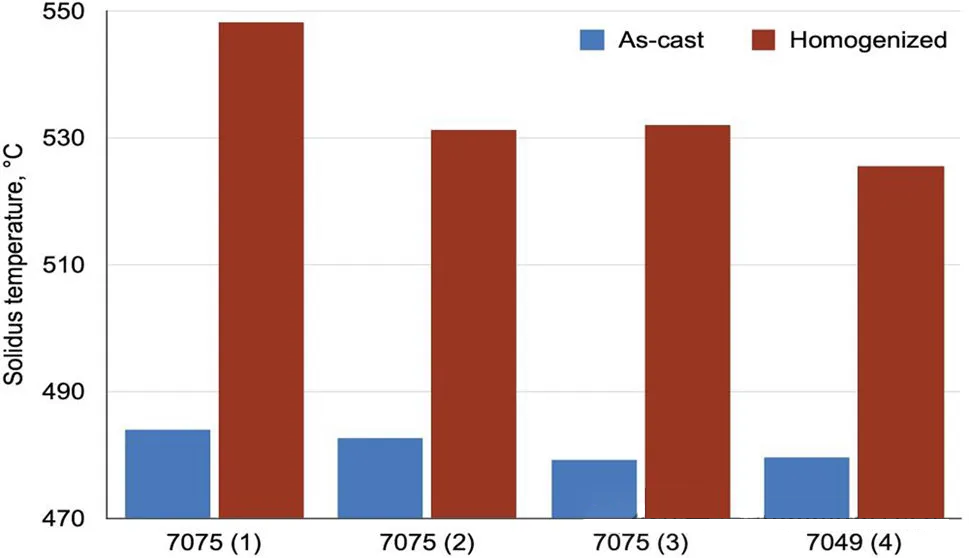

In industrial practice, due to relatively low billet heating rates, plastic deformation during extrusion promotes diffusion and may lead to complete dissolution of certain particles. However, this assumption must be verified experimentally. Results show that billet preheating and extrusion parameters must be carefully optimized. The cooling rate after homogenization influences not only solution heat treatment but also the solidus temperature of the material. Studies have shown that the recommended cooling rate varies significantly with alloy composition. For example, low-Cu 7075 alloy can be slowly cooled at 60 °C/h without affecting the solidus temperature; 7049 alloy performs well under moderate cooling (~120 °C/h); and high-Cu 7075 alloy requires rapid cooling (~500 °C/h), as slower cooling causes a marked decrease in solidus temperature. To recover the high solidus temperature achieved during soaking, billet preheating before extrusion must ensure full dissolution of the S phase.

Port-hole dies are widely used for extruding complex, high-precision hollow aluminum alloy profiles. Die design is challenging and must consider the alloy type, profile geometry, and dimensions, as well as the extrusion press specifications and container diameter, to determine whether single- or multi-hole dies are appropriate. The main design objectives include:

-Minimizing metal flow resistance to reduce extrusion pressure and increase exit speed;

-Reducing elastic die deflection to improve dimensional accuracy and extend die life;

-Regulating metal flow to enhance shape stability and dimensional tolerances;

-Improving stress distribution in the die gaps to prevent tensile-stress-induced surface defects;

-Maximizing strain strength and normal stress in the welding chamber to improve weld quality.

Key design parameters include the number and arrangement of die holes, inlet channel geometry, bridge and mandrel dimensions, welding chamber height, pre-chamber design, and calibration land length. For highly formable and weldable 6xxx series alloys (AlMgSi), even profiles with wall thicknesses of 1 mm or less can be extruded without major issues. Most research efforts focus on optimizing die geometry to adjust metal flow, improve dimensional accuracy of thin-walled complex profiles, and enhance surface quality (mainly by reducing streak lines).

Borowski et al. studied the effects of die design and extrusion speed on dimensional variations of 6082 alloy elliptical profiles (1.25 mm wall thickness). The observed size deviations were mainly attributed to die complexity and deflection. An optimized four-hole, two-step concave die design, successfully applied in industrial practice, enabled metal exit speeds of up to ~14 m/min, while maintaining excellent dimensional accuracy and surface quality. Finite element analysis was used to investigate mandrel elastic deformation and fracture behavior, and further die geometry optimization was achieved using HyperXtrude 13.0 software.

In several severe plastic deformation (SPD) methods, extrusion is the fundamental process — for example, in cyclic extrusion compression (CEC) and equal-channel angular pressing (ECAP). Other well-known SPD techniques include hydrostatic extrusion (HE) and the KOBO process. These methods produce significant microstructural refinement in metals and alloys and facilitate powder material consolidation. Materials deformed through such techniques typically exhibit submicron-sized equiaxed grains separated by highly misoriented grain boundaries. The increased grain boundary density raises stored energy, which affects high-temperature stability and may trigger uncontrolled grain growth, especially in high-purity metals. This limits further grain refinement potential.

In fact, the concept of severe plastic deformation is not new in metal forming — large plastic strains have long been utilized in processes such as forging, rolling, and drawing at both high and low temperatures. However, SPD is distinguished by its ability to produce unique microstructural effects not observed in conventional forming operations. Studies show that microstructural evolution during SPD is strongly dependent on deformation mechanics. By controlling deformation parameters precisely, SPD enables the production of materials with unique combinations of microstructure and properties. Consequently, fine-grained materials have attracted increasing attention over recent decades, driving continuous innovation in metal processing technologies.

Post time: Oct-19-2025