Although virtually all aluminum alloys are extrudable in theory, evaluating the extrudability of a specific part requires a comprehensive consideration of factors such as dimensions, geometry, alloy type, tolerance requirements, scrap rate, extrusion ratio, and tongue ratio. Additionally, it is essential to determine whether direct or indirect extrusion is the more suitable forming method.

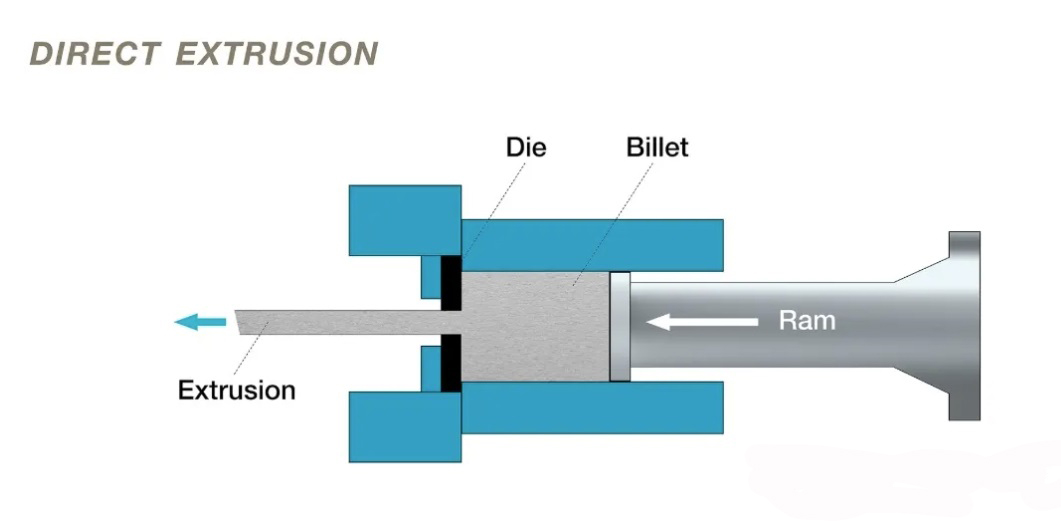

Direct extrusion is the most commonly used process, characterized by its relatively simple design and strong adaptability, making it suitable for a wide range of profile production. In this method, a preheated aluminum billet is pushed by a ram through a stationary die, and the material flows in the same direction as the ram. Friction between the billet and the container is inherent to this process. This friction causes heat buildup and increased energy consumption, leading to variations in temperature and deformation work along the length of the extrusion. Consequently, these variations can affect the grain structure, microstructure, and dimensional stability of the final product. Moreover, since pressure tends to decrease throughout the extrusion cycle, profile dimensions may become inconsistent.

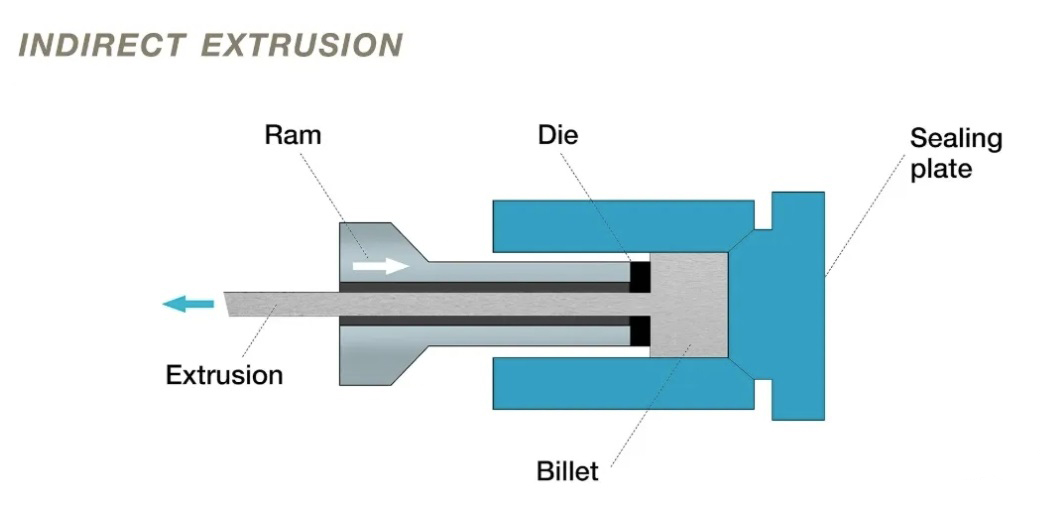

In contrast, indirect extrusion involves a die mounted on the extrusion ram that applies pressure in the opposite direction to a stationary aluminum billet, causing the material to flow in reverse. Because the billet remains static relative to the container, there is no billet-to-container friction. This results in more consistent forming forces and energy input throughout the process. The uniform deformation and thermal conditions achieved through indirect extrusion yield products with improved dimensional accuracy, more consistent microstructure, and enhanced mechanical properties. This method is particularly advantageous for applications requiring high consistency and machinability, such as screw machine stock.

Despite its metallurgical benefits, indirect extrusion has certain limitations. Any surface contamination on the billet can directly affect the surface finish of the extrudate, making it necessary to remove the as-cast surface and maintain a clean billet surface. Additionally, because the die must be supported and allow the extrudate to pass through, the maximum allowable profile diameter is reduced, limiting the size of extrudable shapes.

Due to its stable process conditions, uniform structure, and superior dimensional consistency, indirect extrusion has become a critical method for producing high-performance aluminum rods and bars. By minimizing process variation during extrusion, it significantly enhances the machinability and application reliability of finished products.

Post time: Jul-16-2025