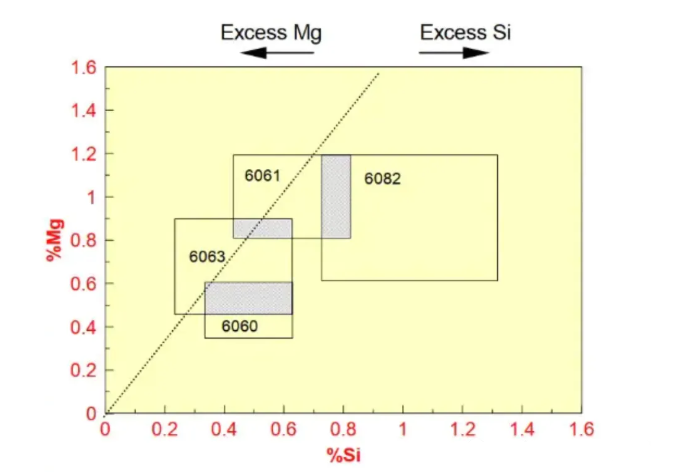

The 6xxx series alloys are typical heat-treatable aluminum alloys, whose strength is derived from heat treatment rather than from mechanical deformation. The key alloying elements are magnesium (Mg) and silicon (Si), which combine to form magnesium silicide precipitates. Some 6000 series alloys and their corresponding Mg and Si contents are shown in the figure. These alloys are designed to have balanced Mg and Si levels or an excess of Si.

Maximum strength in 6000 series extrusion alloys is achieved through the following heat treatment cycle: solutionizing during extrusion or during a separate solution heat treatment process, followed by quenching at an alloy-specific rate, and then age hardening.

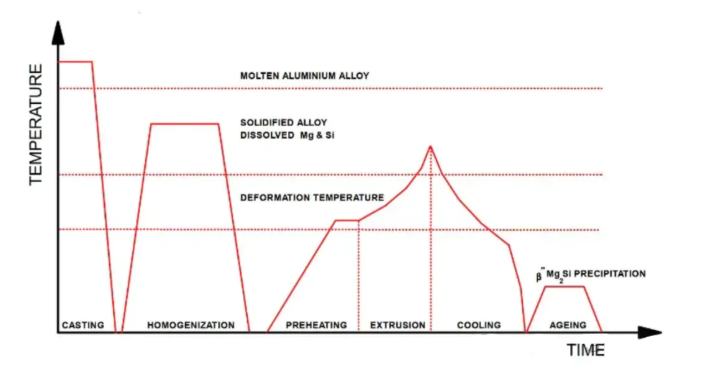

The figure below shows the temperature/time history used to identify the steps during extrusion and the role of Mg and Si in each step.

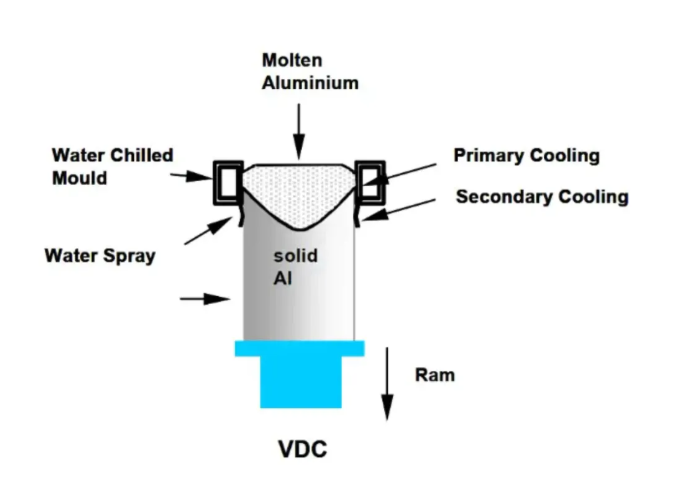

The most common method for producing extrusion billets is vertical direct chill (VDC) casting. Molten aluminum is poured into one or more molds mounted on a table installed on a hydraulic piston. When the metal enters the molds, it solidifies in two stages. The first stage is called primary cooling and involves the solidification of aluminum at the cooled mold walls. This forms a solid aluminum shell surrounding a semi-molten core. Once the solid shell is formed, the piston lowers the bottom of the mold so that the shell comes into contact with a water curtain, initiating the second stage of solidification. During secondary cooling, the metal fully solidifies across the entire billet cross-section. This process can produce multiple continuous billet lengths, for example up to 7 m.

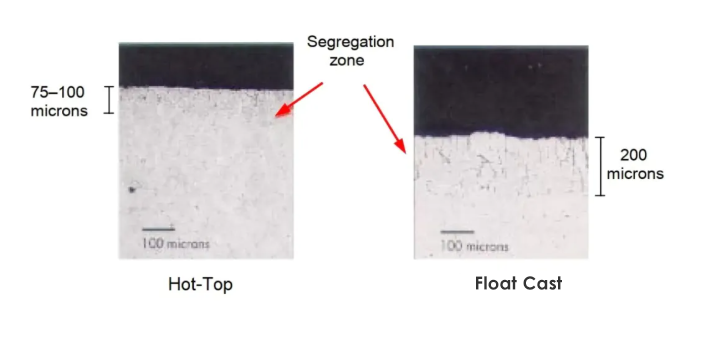

This casting method inevitably leads to the formation of a surface segregation zone approximately 75–200 micrometers thick, depending on the mold design (hot-top or float casting). The cast billet consists of a solid Al matrix containing dissolved Mg and Si, as well as a network of iron-containing particles located at the grain boundaries.

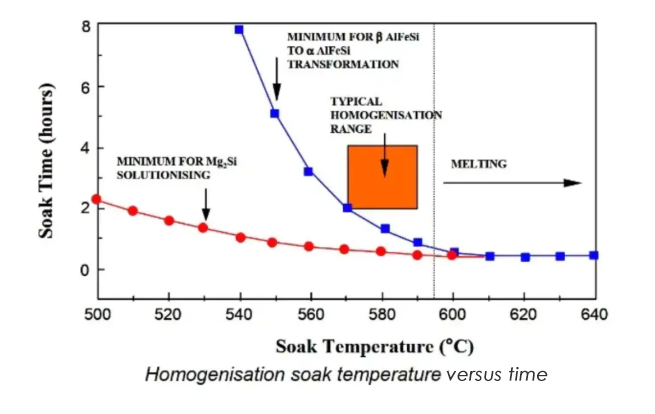

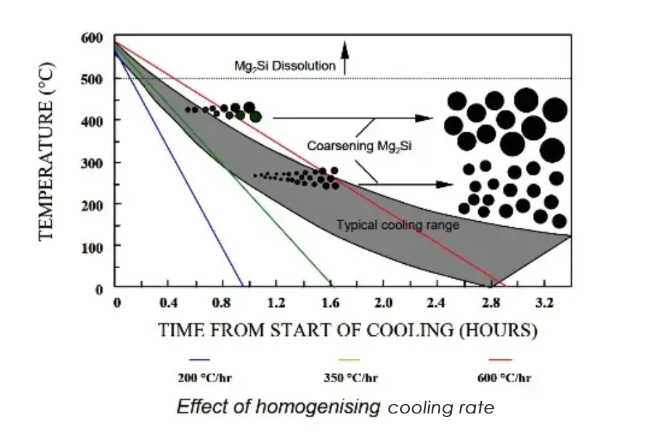

The homogenization cycle is specifically designed to modify the as-cast structure into one that can be extruded at high speed while achieving excellent surface finish and optimal mechanical properties. For low-strength 6000 series alloys containing manganese, a typical homogenization cycle involves heating the billet to 575 °C, holding for 2 to 4 hours, and then cooling the billet at a controlled rate through the critical temperature range of 450 °C to 200 °C.

This cooling practice avoids the formation of precipitates in the microstructure that would be detrimental to the final mechanical properties after extrusion. The homogenization cycle transforms hard, needle-like magnesium silicide intermetallic compounds into more spheroidized intermetallics and ensures a uniform distribution of chemical elements throughout the alloy.

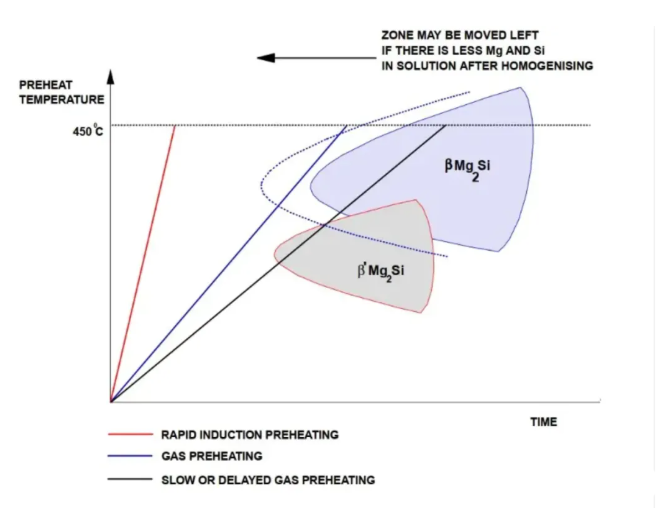

The purpose of preheating the billet for extrusion is to reduce the flow stress of the alloy, allowing extrusion at maximum speed while maintaining excellent surface finish and mechanical properties. The preheating temperature used must be sufficient to dissolve the magnesium silicide precipitates during extrusion. Typical preheating temperatures for lean 6000 series alloys are around 450 °C.

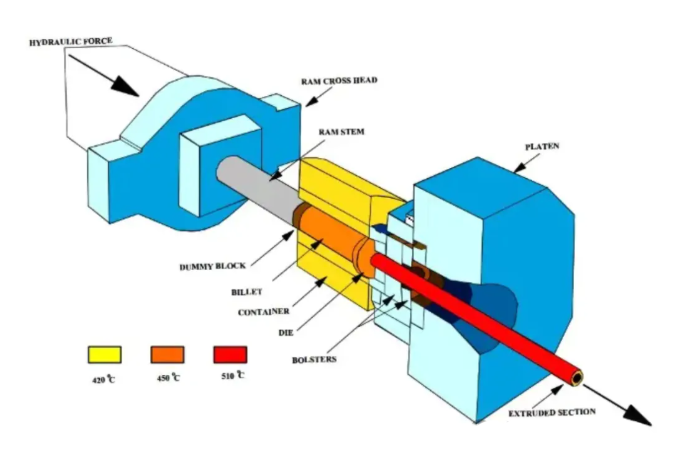

Heat-treatable 6xxx series alloys are most commonly extruded using the direct extrusion process. Aluminum billets are heated to 450–500 °C and loaded into a preheated container (420–470 °C). A hydraulic ram pushes the billet through the die opening. The aluminum flows through the die, producing a continuous extrusion with a cross-section identical to the die aperture.

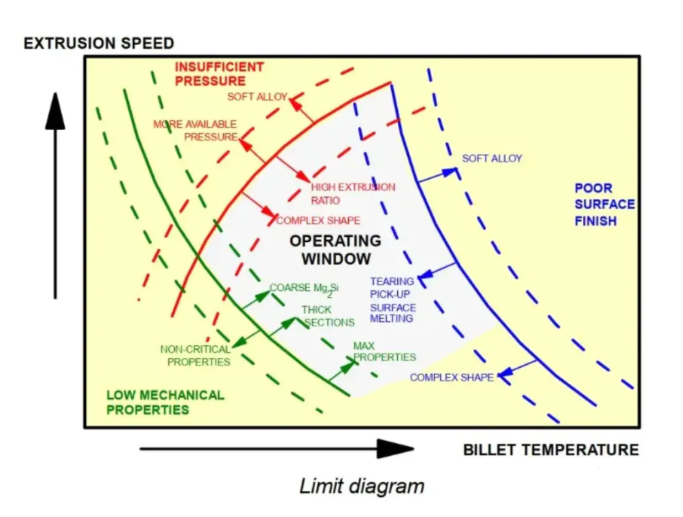

This figure shows a limit diagram and illustrates the concept of the restricted operating window of the extrusion process. Extrusion speed and billet temperature are constrained within these boundaries. Other variables, such as alloy type, extrusion ratio/shape, and final extrusion properties, may expand or reduce the size of the operating window.

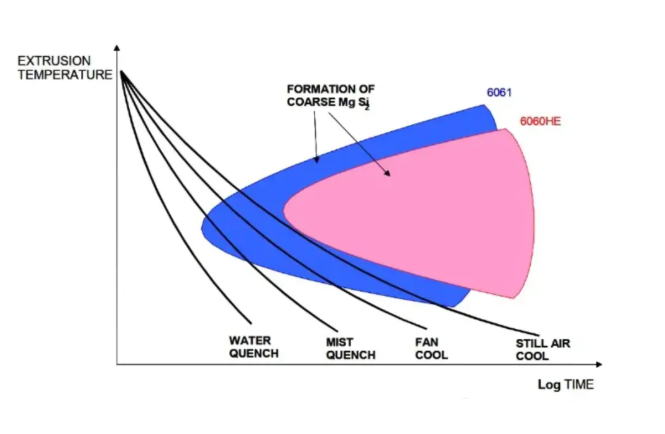

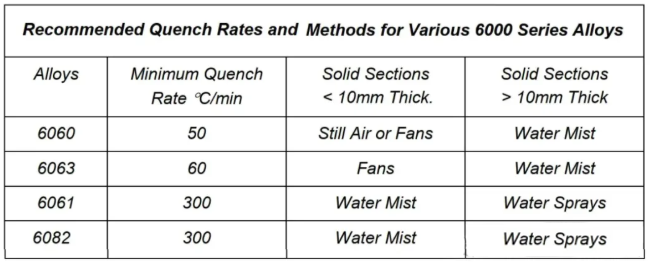

The post-extrusion cooling rate must be sufficiently fast to retain Mg and Si in solid solution so that mechanical properties can be maximized through precipitation during subsequent age hardening. The cooling rate is determined by the cross-sectional size and the cooling method (e.g., still air, fan-assisted air, fine water mist, or water bath). The figure shows adequate cooling for a 6060 alloy, which is typically achieved using still or fan-forced air cooling, whereas harder alloys such as 6061 require fine water mist or immersion cooling.

Typical cooling rates required for some 6000 series alloys are given in the figure below.

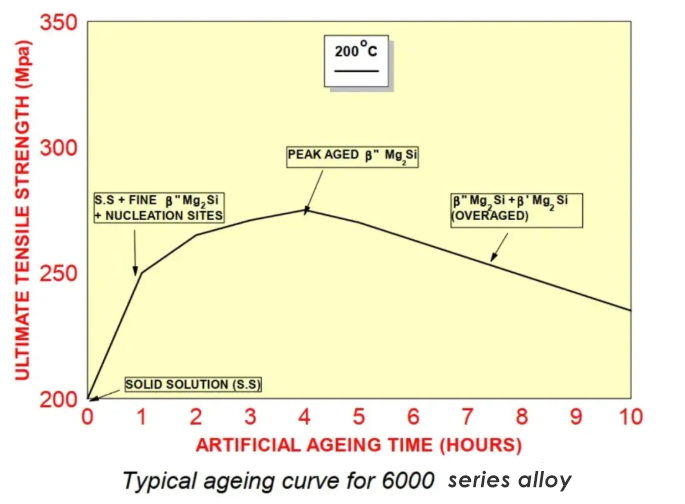

If higher mechanical properties are required, 6000 series extrusions must be aged. The degree of property improvement depends on the alloy type and the aging conditions. These conditions range from natural aging at room temperature to various high-temperature treatments known as artificial aging.

The strength of 6xxx series alloys is directly related to the material’s ability to resist dislocation movement during deformation. The size and density of these precipitates are controlled by the aging conditions. The figure summarizes typical artificial aging curves for 6000 series alloys.

Post time: Dec-27-2025