If the mechanical properties of extrusions are not as expected, attention is usually focused on the initial composition of the billet or the extrusion/aging conditions. Few people question whether homogenization itself could be an issue. In fact, the homogenization stage is crucial for producing high-quality extrusions. Failure to properly control the homogenization step may lead to:

●Increased breakthrough pressure

●More defects

●Streak textures after anodizing

●Lower extrusion speed

●Poor mechanical properties

The homogenization stage has two main purposes: refining iron-containing intermetallic compounds, and redistributing magnesium (Mg) and silicon (Si). By examining the microstructure of the billet before and after homogenization, one can predict whether the billet will perform well during extrusion.

Effect of Billet Homogenization on Hardening

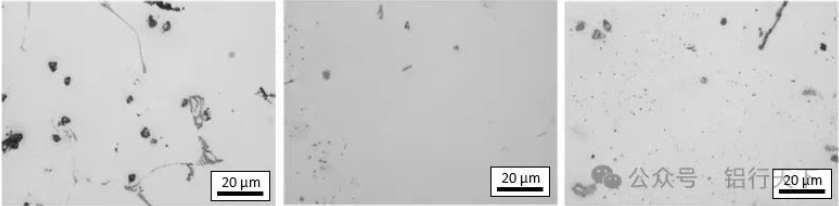

In 6XXX extrusions, strength comes from Mg- and Si-rich phases formed during aging. The ability to form these phases depends on placing the elements into solid solution before aging begins. For Mg and Si to eventually become part of the solid solution, the metal must be quenched quickly from above 530 °C. At temperatures above this point, Mg and Si naturally dissolve into aluminum. However, during extrusion, the metal only remains above this temperature for a short time. To ensure all Mg and Si dissolve, the Mg and Si particles need to be relatively small. Unfortunately, during casting, Mg and Si precipitate as relatively large Mg₂Si blocks (Fig. 1a).

A typical homogenization cycle for 6060 billets is 560 °C for 2 hours. During this process, since the billet stays above 530 °C for a long period, Mg₂Si dissolves. Upon cooling, it re-precipitates in a much finer distribution (Fig. 1c). If the homogenization temperature is not high enough, or the time is too short, some large Mg₂Si particles will remain. When this happens, the solid solution after extrusion contains less Mg and Si, making it impossible to form a high density of hardening precipitates—leading to reduced mechanical properties.

Fig. 1. Optical micrographs of polished and 2% HF-etched 6060 billets: (a) as-cast, (b) partially homogenized, (c) fully homogenized.

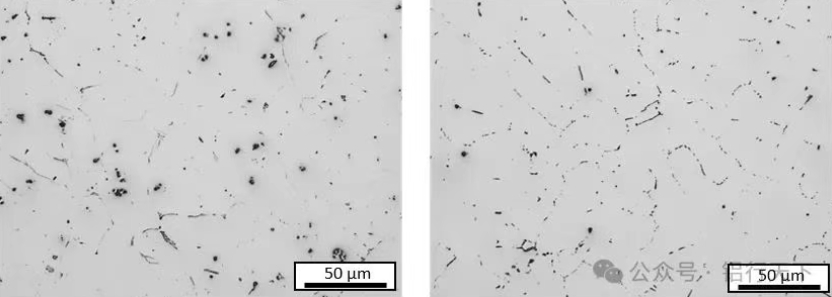

Role of Homogenization on Iron-containing Intermetallics

Iron (Fe) has a greater effect on fracture toughness than on strength. In 6XXX alloys, Fe phases tend to form β-phase (Al₅(FeMn)Si or Al₈.₉(FeMn)₂Si₂) during casting. These phases are large, angular, and interfere with extrusion (highlighted in Fig. 2a). During homogenization, heavy elements (Fe, Mn, etc.) diffuse, and large angular phases become smaller and rounder (Fig. 2b).

From optical images alone, it is difficult to distinguish the various phases, and it is impossible to reliably quantify them. At Innoval, we quantify billet homogenization using our internal feature detection and classification (FDC) method, which provides a %α value for billets. This enables us to assess the quality of homogenization.

Fig. 2. Optical micrographs of billets (a) before and (b) after homogenization.

Feature Detection and Classification (FDC) Method

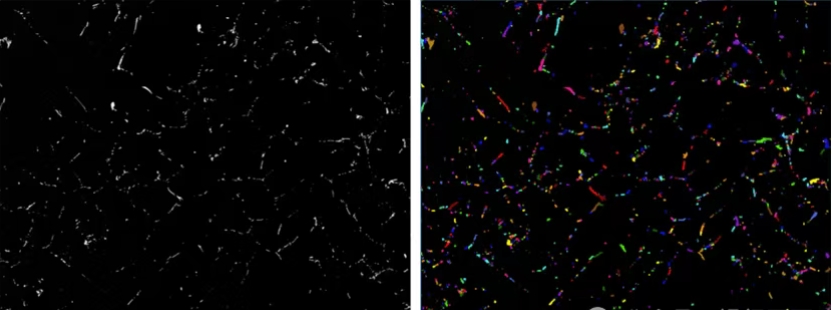

Fig. 3a shows a polished sample analyzed by scanning electron microscopy (SEM). A grayscale thresholding technique is then applied to separate and identify intermetallics, which appear white in Fig. 3b. This technique allows analysis of areas up to 1 mm², meaning over 1000 individual features can be analyzed at once.

Fig. 3. (a) Backscattered electron image of homogenized 6060 billet, (b) identified individual features from (a).

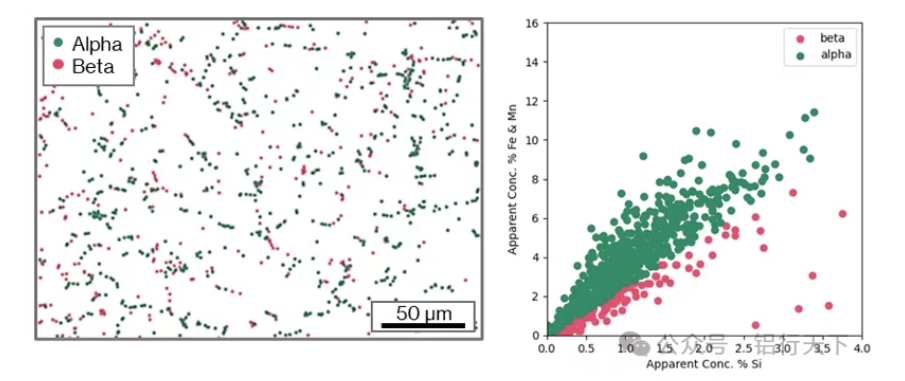

Particle Composition

The Innoval system is equipped with an Oxford Instruments Xplore 30 energy-dispersive X-ray (EDX) detector. This allows fast automatic collection of EDX spectra from each identified point. From these spectra, the particle composition can be determined, and the relative Fe:Si ratio inferred.

Depending on the Mn or Cr content of the alloy, other heavy elements may also be included. For some 6XXX alloys (sometimes with significant Mn), the (Fe+Mn):Si ratio is used as a reference. These ratios can then be compared to those of known Fe-containing intermetallics.

β-phase (Al₅(FeMn)Si or Al₈.₉(FeMn)₂Si₂): (Fe+Mn):Si ratio ≈ 2. α-phase (Al₁₂(FeMn)₃Si or Al₈.₃(FeMn)₂Si): ratio ≈ 4–6, depending on composition. Our custom software allows us to set a threshold and classify each particle as α or β, then map their positions within the microstructure (Fig. 4). This gives an approximate percentage of transformed α in the homogenized billet.

Fig. 4. (a) Map showing α- and β-classified particles, (b) scatter plot of (Fe+Mn):Si ratios.

What the Data Can Tell Us

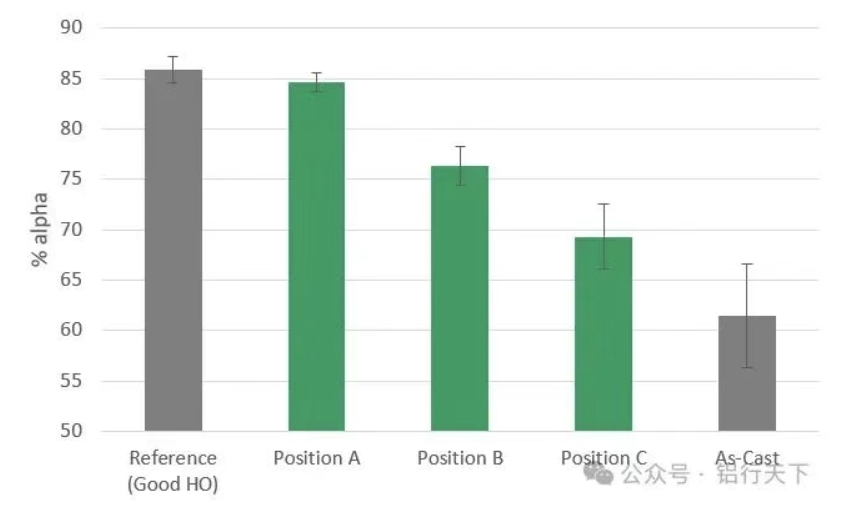

Fig. 5 shows an example of how this information is used. In this case, the results indicate non-uniform heating within a specific furnace, or possibly that the setpoint temperature was not reached. To properly assess such cases, both the test billet and reference billets of known quality are required. Without these, the expected %α range for that alloy composition cannot be established.

Fig. 5. Comparison of %α in different sections of a poorly performing homogenization furnace.

Post time: Aug-30-2025