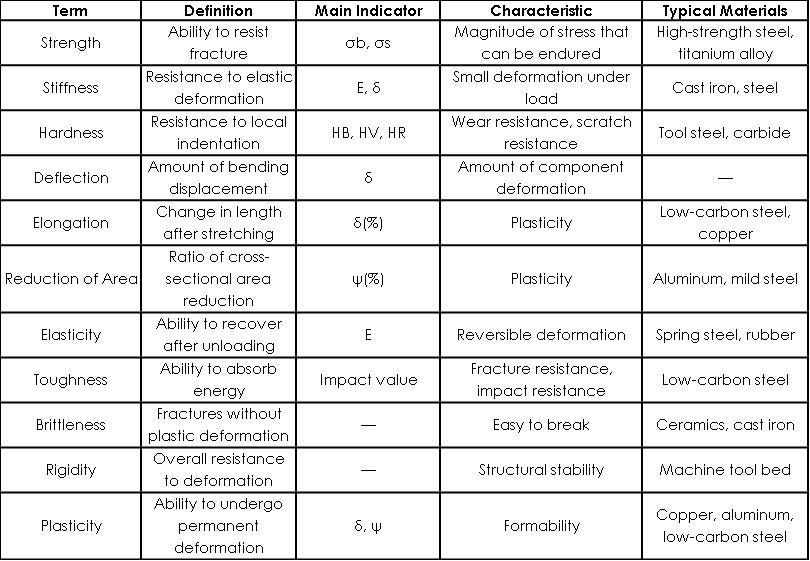

Basic Information

1. Strength

Definition:The ability of a material to resist failure, or to resist permanent deformation or fracture.

Common Indicators:Yield strength, tensile strength, compressive strength, bending strength, etc.

Meaning:The extent of stress a material can withstand without failure.

High strength ≠ small deformation, and it does not mean non-brittle.

a. Tensile Strength

The maximum stress a material can withstand under tensile load. It represents the material’s capacity to bear tension.

b. Compressive Strength

The maximum stress a material can withstand under compressive load. It represents the material’s capacity to resist compression.

c. Shear Strength

The maximum stress a material can withstand under shear load. It represents the material’s ability to resist shearing forces.

d. Flexural Strength

The maximum stress a material can withstand under bending load. It describes the material’s ability to resist flexural stress.

e. Fatigue Strength

The maximum stress a material can withstand under cyclic loading. It describes the durability of materials under repeated stress conditions.

f. Impact Strength

The ability of a material to resist impact loading. It measures the strength of materials under sudden or high-speed loads.

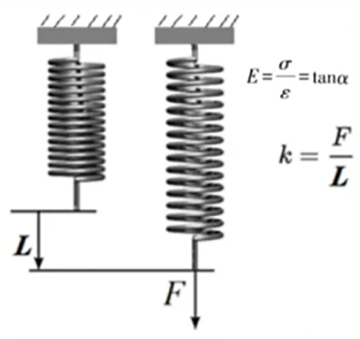

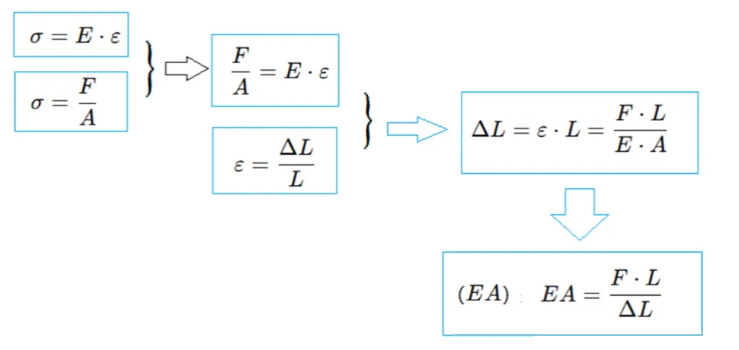

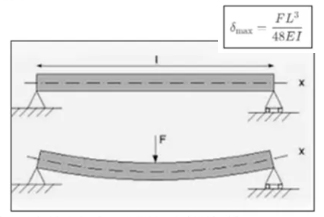

2.Stiffness

Definition:The ability of a material or structure to resist elastic deformation.Indicator:Elastic modulus (E) and structural deflection (δ).

Meaning:For the same load, the smaller the deformation, the greater the stiffness.

A material with high stiffness does not necessarily have high strength (e.g., cast iron has high stiffness but is brittle).

Tensile stiffness (also called tensile elastic stiffness) is a measure of a material’s or structure’s ability to resist elongation deformation under tensile loading.

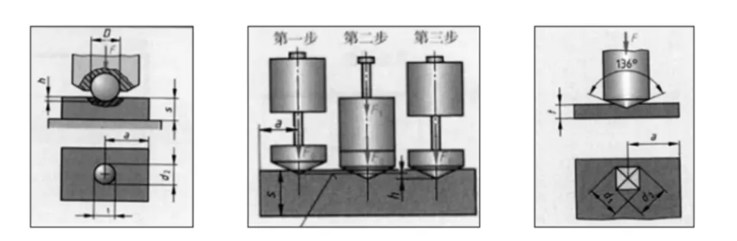

3.Hardness

Definition: The ability of a material’s surface to resist external forces, particularly local plastic deformation (indentation or scratching).

Common Testing Methods: Brinell hardness (HB), Rockwell hardness (HR), Vickers hardness (HV).

Meaning: Resistance to wear and scratching.

Related to strength but not equivalent (ceramics are hard but brittle; steel is both hard and tough).

4. Deflection

Definition:The amount of bending displacement that occurs in a structural member under load.

Criterion:The maximum deflection at the midpoint of the beam.

Meaning:The larger the deflection, the lower the stiffness.

Deflection is a direct indicator of structural stiffness.

Excessive deflection may lead to structural vibration or functional failure.

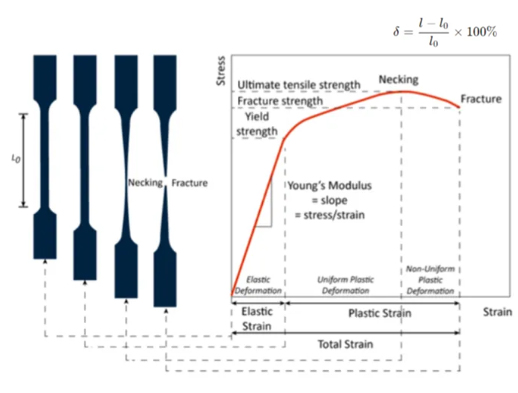

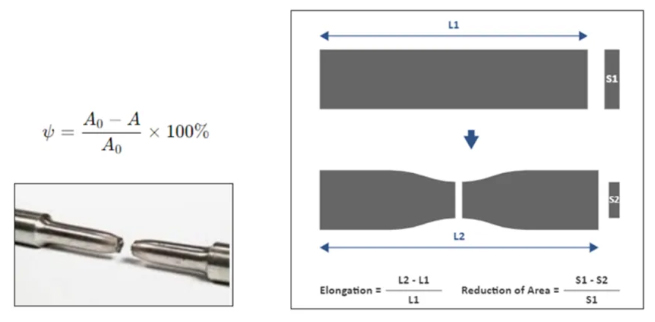

5.Elongation (Tensile Strain)

Elongation reflects the degree of deformation a material undergoes during a tensile test.

In a tensile test, the material deforms before it fractures. The elongation is equal to the increase in length after fracture divided by the original length of the specimen.

Since the material deforms before fracture, the cross-sectional area at the fracture point becomes smaller than the original cross-sectional area.

The reduction of area is equal to the decrease in cross-sectional area divided by the original cross-sectional area of the specimen.

6. Reduction of Area

Definition:The percentage decrease in cross-sectional area after tensile fracture.

Meaning:It reflects the material’s ability to undergo necking and is an indicator of plasticity.

It is often used together with elongation to evaluate the plasticity of a material.

7.Elasticity

Definition:The ability of a material to return to its original shape after the removal of a load that caused deformation.

Criterion:Elastic modulus E.

Meaning:The deformation is reversible.

Good elasticity ≠ small deformation (for example, rubber has good elasticity but a low E).

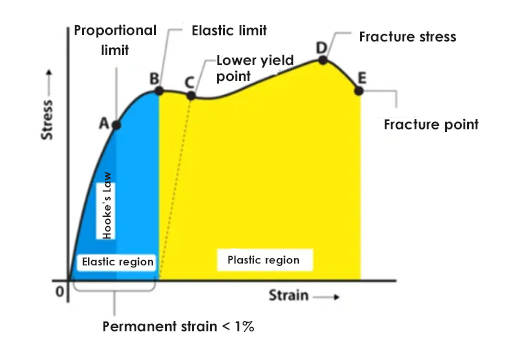

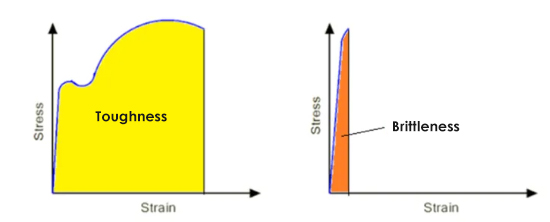

8. Toughness

Definition:The ability of a material to absorb energy before impact or fracture.

Criterion:

Impact absorption energy, or the area under the stress–strain curve (see Figure 1).

Meaning:A tough material can withstand high stress while exhibiting significant plastic deformation.

High toughness = high strength + good ductility.

9. Brittleness

Definition:A property of a material that exhibits almost no plastic deformation before failure under load.

Criterion:Very small elongation or reduction of area.

Meaning:Brittle materials tend to fracture suddenly.

Brittleness is the opposite of toughness; ceramics, glass, and cast iron are typical brittle materials.

10. Rigidity

Definition:The ability of a structure or system as a whole to resist deformation.

Distinction:Stiffness refers more to the local deformation resistance of a material or component.

Rigidity emphasizes the overall stability of the system — its resistance to shaking, vibration, or deflection.

Example:A machine tool with good rigidity operates stably and maintains high precision.

11. Plasticity

Definition:The ability of a material to undergo permanent deformation under external force without breaking.

Manifestation:High elongation and high reduction of area.

Meaning:Good plasticity means the material can be stretched or forged without easily fracturing.

Post time: Nov-01-2025