In aluminum extrusion workshops, one of the most challenging issues is not the roar of the machines, but the underperformance of meticulously prepared and costly dies once they are mounted. Improperly functioning dies can produce profiles with uneven walls, inconsistent lengths, or even cause blockages that necessitate immediate removal and repair. These incidents not only reduce production efficiency but also result in significant financial loss.

The design and fabrication of dies can account for nearly 20% of total production costs. Therefore, improving the first-time success rate of die operation directly impacts both productivity and profitability. Based on practical experience, there are four critical actions that operators and die maintenance personnel can implement immediately to maximize die performance and operational success.

First, ensure that aluminum billets are uniformly heated throughout their cross-section. Many extrusion defects originate before the billet enters the extrusion barrel. Specified heating temperatures and holding times are not arbitrary—they are essential for preventing internal inconsistencies. Billets must be fully heated at both the surface and the core; for example, the surface may reach 480–500°C, while the core requires 530–550°C. Insufficient core temperature can lead to uneven die deformation under high extrusion pressure, causing wall thickness variation or length discrepancies, and in severe cases, permanent die damage.

Second, precise alignment of the extrusion system is crucial. The barrel, ram, and die must share a common central axis to ensure even metal flow. Any misalignment can cause uneven pressure distribution, particularly in multi-hole dies, resulting in inconsistent extrusion speed across the openings and defective profiles. Careful visual inspection, supplemented by measuring tools if available, is necessary before starting the press. Misalignment is akin to applying force with a bent rod—it cannot transmit pressure uniformly, and the die suffers accordingly.

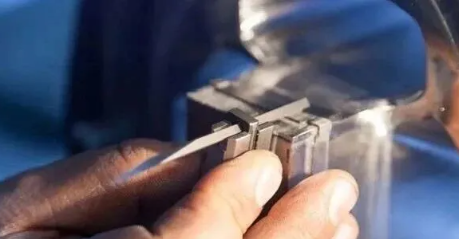

Third, proper support for the die is essential to minimize elastic deformation during extrusion. Dies, especially lower dies and mandrels, behave like springs under high tonnage pressure. Using appropriately sized and preheated support pads provides a stable foundation, reducing deformation and ensuring dimensional consistency. The support pads should be preheated to 350–450°C to prevent thermal shock when hot dies are placed on cold steel surfaces, which could otherwise result in cracking, warping, or extrusion difficulties.

Finally, accurate and detailed feedback from the extrusion output is indispensable for die maintenance. Operators must provide precise information about blockages, deviations, or dimensional discrepancies. For multi-hole dies, indicating flow directions and speed differences on the billet or scrap, along with specific measurements, allows maintenance personnel to diagnose issues accurately. Incorrect or incomplete feedback can lead to inappropriate repairs, further compromising die performance.

A die embodies the cumulative effort of design, fabrication, and operational preparation. While design and machining form the foundation, controlled extrusion processes and systematic information reporting are critical for maximizing die value. Strict adherence to proper billet heating, system alignment, and die support creates the optimal operational environment, while precise feedback enables effective maintenance. The coordinated execution of these practices ensures high first-time success rates, protecting both production efficiency and investment.

Post time: Dec-20-2025