Aluminum Extrusion Process

The aluminum extrusion process is a highly efficient and versatile manufacturing technique used to produce aluminum parts with varying cross-sectional profiles.

Among all the tools involved, the most critical component is the extrusion die. It plays a key role in this process, shaping the aluminum as it is forced through the die opening under immense pressure, requiring incredible precision and reliability.

The extrusion process typically involves the following steps:

Billet Preheating: The aluminum billet (a solid aluminum log) is preheated to the required temperature based on the alloy, typically around 700-930°F (370-500°C), to achieve the plasticity needed for extrusion.

Loading: The preheated billet is loaded into the heated container, which is part of the extrusion press.

Ram Advance: A hydraulic ram applies immense pressure, typically ranging from 1,000 to 15,000 tons, to force the softened aluminum through the die opening.

Profile Extrusion: As the aluminum is pushed through the die, it takes on the shape of the die opening, forming the desired profile.

Profile Cooling and Handling: The extruded profile is cooled, either by air or water, and then transferred for further processing such as stretching, machining, and surface treatment.

Throughout the extrusion process, the die plays a crucial role in maintaining dimensional accuracy, surface finish, and overall product quality. Factors such as die design, material flow, and thermal management significantly impact extrusion quality and efficiency.

What is an Aluminum Extrusion Die?

An aluminum extrusion die contains a meticulously designed opening that determines the cross-sectional shape of the extruded profile. It is placed in the extrusion press along with various support tools such as backers, bolster plates, and/or sub-bolsters, which provide structural support and alignment during the high-pressure extrusion process. Requirements for this support tooling vary significantly depending on the type of die used.

Types of Aluminum Extrusion Dies

Aluminum extrusion dies can be broadly categorized into three main types based on their design and intended use: solid, hollow, and semi-hollow. Each consists of multiple components, collectively referred to as the “die stack.”

Solid Dies

Solid dies are used to produce solid aluminum profiles without any enclosed voids. These dies are suitable for simple shapes such as bars, angles, and channels. Solid dies are generally less complex and more cost-effective compared to other die types.

The three components of a solid die stack include the feeder plate, the die itself, and the backer plate.

Feeder Plate: In some cases, a feeder plate is used to provide additional control over aluminum flow, facilitating continuous flow from one billet to the next and controlling the profile and spread of the aluminum.

Die: The die itself contains the final opening through which the aluminum passes, creating the finished profile shape.

Backer Plate: The backer plate is used to reinforce the die during the extrusion process.

Hollow Dies

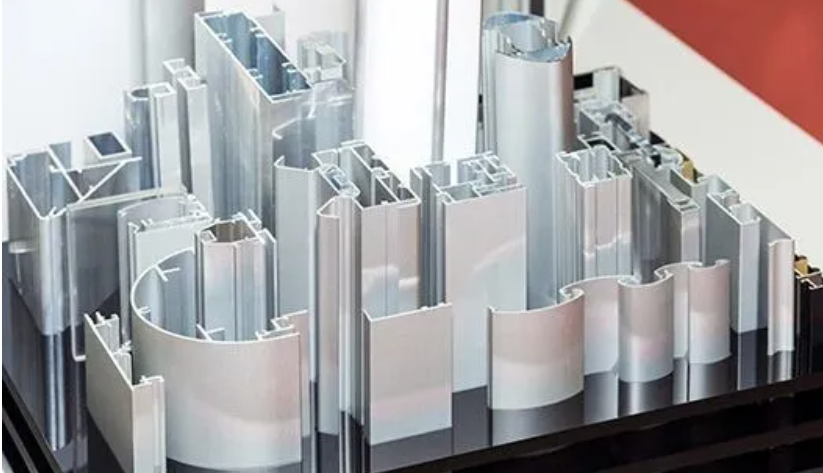

Hollow dies are designed to produce aluminum profiles with internal cavities or hollow sections. These dies are ideal for complex shapes such as tubes, window frames, and structural members with internal reinforcement.

The three components of a hollow die stack include the mandrel, the die, and the backer plate.

• Mandrel: The mandrel has a void that forms the hollow part of the die. Aluminum flows around the void, creating the desired hollow shape.

• Die: The die is the outer part of the die assembly, which holds the mandrel in place and shapes the outer contour of the aluminum profile. It has a contour that matches the desired external shape of the final product.

• Backer Plate: Just like with solid dies, hollow dies require a backer plate to reinforce the die during extrusion. It also aids in thermal management, preventing excessive heat loss from the die stack.

Semi-Hollow Dies

Semi-hollow dies combine elements of both solid and hollow dies. They are used to produce aluminum profiles that have both solid and hollow sections within the same cross-section. These dies offer versatility in profile design and can accommodate complex geometries with varying wall thicknesses.

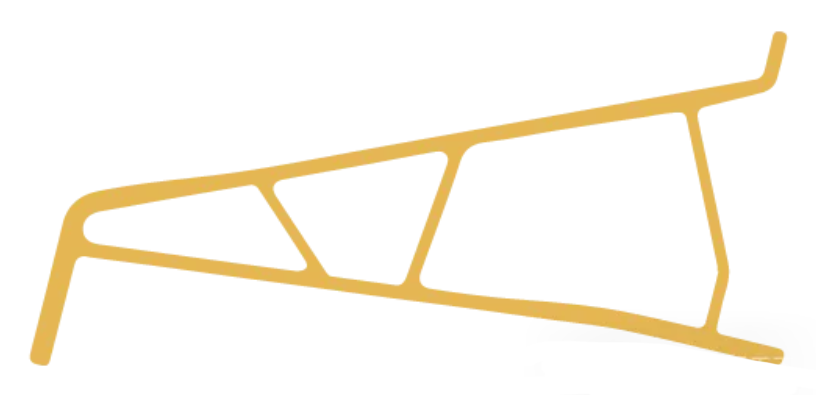

Profile Shapes

Aluminum extrusion dies can be designed to produce a wide variety of profile shapes and configurations, ranging from standard profiles to highly customized designs.

Extrusion Tooling

The extrusion die is the core of aluminum shaping; however, it cannot function alone. It is part of an overall assembly system that works as a cohesive unit to ultimately produce the extrusion. We can categorize these components into two groups: support tooling and extrusion press tooling.

Support Tooling

Extrusion dies are subjected to pressures up to 15,000 tons during the extrusion process. Therefore, the die requires heavy-duty support tooling to ensure it remains perfectly aligned and secure during this process.

Consequently, the die requires heavy-duty support tooling to ensure it remains perfectly aligned and secure during this process. Support tooling requirements vary based on the type of die used and the operating parameters of the press.

Extrusion Press Tooling

The aluminum extrusion process relies on a comprehensive set of extrusion press tooling to control the billet temperature and push the aluminum through the die.

Extrusion press tooling is required regardless of the type of die used. Key extrusion press tooling components include the extrusion stem, dummy block, container, liner, slide, and horseshoe ring.

Effective Die Design

Effective die design is a critical aspect of the aluminum extrusion process as it directly impacts quality, efficiency, and cost-effectiveness.

In practice, the design process relies heavily on the designer’s experience and intuition. However, designers consider several key principles and techniques in every die design.

process relies heavily on the designer’s experience and intuition. However, designers consider several key principles and techniques in every die design.

• Uniform Material Flow Velocity: The most important factor for improving extrusion quality and extending die life is ensuring smooth and uniform material flow. This minimizes potential defects such as turbulence, dead zones, and warping. Techniques include modifying die bearing lengths, adjusting pocket lengths, and incorporating runners or feeders.

• Optimal Bearing Length: The bearing length, or the distance the aluminum travels inside the die, should be carefully calculated so that all parts of the profile exit the die at the same speed. Longer bearing lengths increase resistance to aluminum flow, slowing it down, while shorter bearing lengths do the opposite. Therefore, longer bearing lengths should be used to slow down thicker areas of the profile to match the speed of thinner areas.

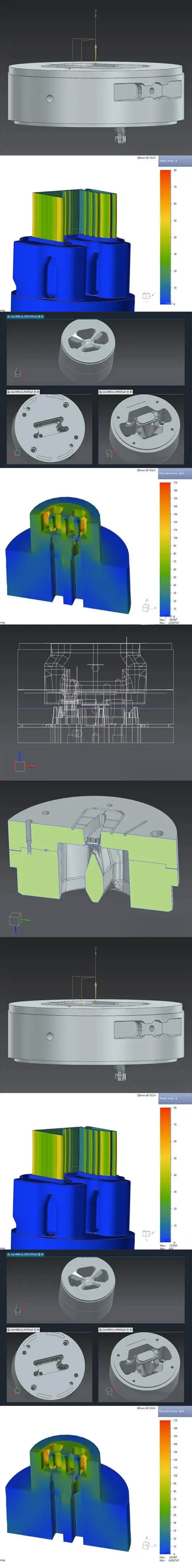

• Finite Element Analysis (FEA): FEA simulations should be used to model the extrusion process and analyze the die’s structural integrity, thermal behavior, and material flow characteristics to identify potential issues before manufacturing the die.

• Thermal Management: The temperature of the aluminum as it exits the die greatly influences the mechanical properties and surface quality of the extrusion. Effective cooling and heating strategies should be employed in die design to maintain consistent temperatures and prevent defects caused by thermal variations.

• Surface Treatment: Advanced surface treatments and coatings, such as nitriding, chrome plating, or hard coatings, enhance die performance, improve wear resistance, extend die life, and contribute to the smoothness of the extrusion.

• Material Selection: Selecting the appropriate material is crucial for ensuring performance and durability. H13 steel, with its excellent thermal conductivity, wear resistance, and toughness, is sufficient for nearly all dies.

The cost of aluminum extrusion dies is influenced by various factors affecting both initial investment and ongoing expenses.

• Design and Planning: Efficient die design and process planning are crucial for reducing overall costs. Utilizing advanced design tools such as feature-based neural networks and CAD systems helps optimize the design process, minimizing errors and rework.

• Die Maintenance and Rework: Routine maintenance and repairs must be considered. Efficient die correction practices help extend die life, minimize downtime, and reduce costs associated with die failure.

• Die Material: Material selection is a balance between initial production cost, performance, and die life. Despite a higher initial cost, high-quality tool steels like H13 are often preferred due to their excellent wear resistance and durability, leading to long-term savings in downtime, maintenance, and repair costs.

• Die Complexity: More complex profiles with intricate details or internal features typically require more extensive manufacturing processes, increasing the die’s cost. Furthermore, the more complex the die, the higher the maintenance and wear, increasing ongoing expenses.

• Manufacturing Process: The specific manufacturing techniques employed, such as CNC machining, wire EDM, or surface treatments, influence die cost. Advanced machining processes can improve precision but come with higher initial costs. Surface treatments like nitriding or coatings can enhance durability but add to the initial manufacturing cost.

• Production Volume: Higher production volumes may justify investing in more expensive die materials or manufacturing processes to extend die life and reduce the total cost per unit.

Extrusion Die Maintenance and Troubleshooting

Proper maintenance and troubleshooting of aluminum extrusion dies are essential for ensuring consistent performance, maximizing die life, and minimizing downtime.

Some common die issues and maintenance practices include:

Wear: Over time, the die opening experiences wear due to the high pressure and temperatures involved in the extrusion process. Regular inspection and preventive maintenance, such as resurfacing or repolishing, can extend die life.

Surface Defects: Defects on the die surface, such as scratches, dents, or buildup, can cause imperfections in the extruded profile. Proper cleaning and surface treatment can help mitigate these issues.

Thermal Management: Uneven heating or cooling of the die can lead to distortion, cracking, or inconsistent material flow. Ensuring proper thermal management through effective cooling systems and insulation is crucial.

Alignment and Support: Misalignment or insufficient support of the die stack components can lead to dimensional inaccuracies or premature die failure. Regular inspection and adjustment are necessary to maintain proper alignment.

Preventive Maintenance: Implementing a comprehensive preventive maintenance program, including regular inspection, cleaning, and refurbishment, can significantly extend die life and reduce unplanned downtime.

Advanced diagnostic tools, such as Finite Element Analysis and simulation software, can help identify root causes and develop targeted solutions for die-related issues.

Industry Standards and Best Practices

Adherence to industry standards and best practices is crucial for ensuring product quality, safety, and compliance with regulatory requirements.

Some prominent organizations and associations responsible for developing these guidelines for the aluminum extrusion industry include:

Aluminum Extruders Council (AEC)

The AEC publishes guidelines and best practices for the aluminum extrusion process, including die design, tooling, and extrusion parameters.

European Aluminum Association (EAA)

The EAA develops standards and guidelines specifically for the European aluminum industry, covering aspects such as alloy specifications, extrusion practices, and quality assurance.

International Organization for Standardization (ISO)

ISO standards cover various aspects of aluminum extrusion, including material specifications, dimensional tolerances, and quality management systems.

ASTM International

ASTM provides standards for aluminum alloy designations, mechanical properties, and testing methods, which are widely recognized and adopted globally.

In addition to complying with industry standards, implementing best practices in die design, manufacturing, and extrusion processes is essential for achieving optimal performance and quality.

Best practices include:

Utilizing advanced design tools and simulation software for die optimization

Implementing robust quality control measures during die manufacturing

Conducting thorough testing and validation of new die designs

Establishing preventive maintenance and refurbishment schedules for die stacks

Fostering continuous improvement through regular process reviews and knowledge sharing

By adopting industry standards and best practices, manufacturers can ensure compliance, enhance product quality, and foster a culture of excellence within the aluminum extrusion industry.

Emerging Trends and Future Developments

Driven by technological advancements, evolving market demands, and a focus on improving efficiency, precision, and die longevity, the aluminum extrusion industry is continuously evolving.

Several emerging trends and future developments are shaping the landscape of aluminum extrusion technology:

• Artificial Intelligence: AI and machine learning are increasingly used to optimize die design and process parameters for improved efficiency and reduced waste. These systems leverage data analysis and machine learning algorithms to identify potential design and process issues, predict optimal extrusion parameters, and facilitate predictive maintenance.

• Advanced Coatings: Development of new coatings is ongoing, but based on our experience as aluminum extrusion die experts, more R&D is needed before they become feasible or cost-effective for most applications.

• Additive Manufacturing for Die Production: A significant advancement is the application of additive manufacturing in creating complex die geometries. Techniques such as Selective Laser Melting (SLM) allow for the production of dies with integrated conformal cooling channels, enhancing thermal management and increasing productivity.

• Simulation and Modeling: The use of advanced simulation software and modeling techniques is becoming more prevalent in die design and optimization. These tools allow for virtual prototyping, predictive analysis of material flow and thermal behavior, and streamlined design iterations, ultimately leading to more efficient and cost-effective die solutions.

• Sustainable and Energy-Efficient Practices: With growing focus on environmental sustainability, the aluminum extrusion industry is exploring ways to reduce energy consumption, minimize waste, and implement environmentally friendly practices throughout the die lifecycle. This includes optimizing die designs for energy efficiency, exploring alternative materials and manufacturing processes, and implementing recycling and reuse programs.

These advancements are driving the aluminum extrusion industry towards greater precision, efficiency, and sustainability to meet the evolving demands of various sectors such as automotive, aerospace, and construction.

The aluminum extrusion process relies heavily on the precision and reliability of the extrusion die. Understanding the different types of dies, their components, and the involved support and press tooling is essential for optimizing the extrusion process.

Post time: Oct-08-2025