Aluminum deep-processing casting is a core link in the aluminum alloy industry chain. Product quality at this stage directly determines the performance of downstream components used in aerospace, new energy vehicles, high-end equipment, and other advanced fields. With the revision and implementation of national standards, increasingly stringent requirements have been imposed on ingot mechanical properties, internal quality, and dimensional accuracy.

In actual production, five major defects—porosity, inclusions, coarse grains, shrinkage cavities/shrinkage porosity, and cracking—have long plagued the industry. Statistics show that defects caused by these issues account for more than 85% of total casting scrap, directly resulting in losses exceeding RMB 1,500 per ton of aluminum products.

Grain refinement technology improves the ingot microstructure through heterogeneous nucleation, while melt purification technology focuses on removing gases and inclusions from the melt. The combined application of these two technologies has become the core solution for eliminating casting defects. Based on the latest industry standards and enterprise-level practical cases, this article systematically analyzes the formation mechanisms of the five major defects and provides a detailed, actionable guide covering operational methods, parameter control, and equipment selection, enabling aluminum processing enterprises to implement these solutions directly.

I. In-Depth Analysis of the Formation Mechanisms of the Five Major Casting Defects in Aluminum Deep Processing

(1) Porosity Defects: The Dual Effect of Melt Gas Absorption and Gas Entrapment

Porosity is the most common defect in aluminum casting, appearing as circular or elliptical voids inside or on the surface of ingots, typically with diameters ranging from 0.1 to 5 mm. It seriously compromises material density and mechanical properties. Its formation mainly originates from three key stages:

Gas absorption by the melt:

At temperatures above 700°C, molten aluminum rapidly absorbs gases such as water vapor and carbon dioxide from the air, with hydrogen having the highest solubility. On average, 100 g of molten aluminum can dissolve about 0.25 cc of hydrogen. Insufficient drying of refractory materials, moist charge surfaces, and air entrainment during melting all intensify gas absorption.

Obstructed gas escape:

During casting, excessively high filling speeds or unstable flow fields prevent gases from floating out in time. Additionally, overly rapid cooling in the mold may cause gases to be trapped by the solidified shell, forming dispersed porosity.

Imbalanced process parameters:

Excessively high casting temperatures increase gas solubility, while excessively low temperatures reduce melt fluidity. Both conditions lead to higher porosity rates.

(2) Inclusion Defects: A Chain Reaction of Melt Contamination and Filtration Failure

Inclusions mainly include oxide inclusions (Al₂O₃), refractory debris, and refining agent residues. They are irregularly distributed within the ingot and disrupt matrix continuity, significantly reducing tensile strength and fatigue life. Their causes can be summarized as follows:

Melt oxidation:

When molten aluminum contacts air, it rapidly forms an oxide film. During pouring, this film may rupture and be entrained into the melt, forming endogenous inclusions.

External contamination:

Spalling from refractories in furnace linings, launders, and molds, as well as impurities in scrap aluminum that are not thoroughly removed, are major sources—especially prominent in recycled aluminum production.

Insufficient purification processes:

Incomplete refining or ineffective filtration due to oversized or clogged filter media prevents effective removal of inclusions. According to data from the China Nonferrous Metals Processing Industry Association, casting lines without efficient purification processes can exhibit inclusion contents exceeding 0.08%.

(3) Coarse Grain Defects: The Inevitable Result of Insufficient Nucleation and Uncontrolled Growth

Coarse grains are characterized by α-Al grain sizes exceeding 100 μm, leading to low strength, poor plasticity, and a high tendency for cracking during subsequent processing. The primary causes include:

Lack of nucleation sites:

During solidification of pure aluminum melts, heterogeneous nucleation sites are scarce. Relying solely on homogeneous nucleation makes it difficult to form fine grains.

Improper process parameters:

Excessively high casting temperatures prolong grain growth time, while slow cooling rates allow grains to grow excessively—particularly problematic in large-diameter billet production.

Alloy composition effects:

Aluminum alloys containing elements such as Zr and Si may react with grain refiners, causing “poisoning” and deactivation of the refiner, thereby exacerbating grain coarsening.

(4) Shrinkage Cavities and Shrinkage Porosity: Direct Manifestations of Solidification Shrinkage and Insufficient Feeding

Shrinkage cavities and shrinkage porosity are typically distributed in the ingot center or hot spots. Shrinkage cavities are large, concentrated voids, while shrinkage porosity consists of fine, dispersed pores. Both reduce material density and pressure resistance. Their formation mechanisms include:

Solidification shrinkage characteristics:

Aluminum alloys experience a volume shrinkage of approximately 6%–8% during solidification. If insufficient molten metal is supplied, shrinkage voids form.

Unreasonable temperature gradients:

Uneven cooling in the mold leads to disordered solidification sequences. When the ingot center solidifies last, the surrounding solid shell has already formed, preventing effective feeding.

Process design flaws:

Improper riser design or excessive fluctuations in casting speed can block feeding channels, resulting in shrinkage defects.

(5) Cracking Defects: A Combined Reflection of Stress Concentration and Insufficient Plasticity

Cracks are classified into hot cracks and cold cracks. Hot cracks form during solidification, while cold cracks develop during cooling. Both lead to direct ingot rejection. Their main causes include:

Thermal stress and structural stress:

Uneven cooling creates large internal–external temperature differences, generating thermal stress. Meanwhile, phase transformations during solidification cause volume changes, producing structural stress. When the combined stress exceeds the tensile strength of the material, cracks occur.

Imbalanced process parameters:

Excessive casting speed or overly high cooling water pressure results in an overly thin solidified shell, while excessively low melt temperatures reduce fluidity—both increasing crack susceptibility.

Insufficient material plasticity:

Factors such as coarse grains and excessive inclusions reduce high-temperature plasticity, making ingots more prone to cracking under stress.

II. Core Principles and Practical Implementation of Grain Refinement Technology

Grain refinement technology improves the mechanical properties of aluminum alloys by introducing heterogeneous nucleation particles into the molten aluminum, thereby lowering the nucleation energy barrier and promoting the refinement of α-Al grains. At the same time, it helps reduce defects such as segregation and porosity.

At present, chemical grain refinement is the most widely applied industrial method, often supplemented by physical grain refinement techniques to further enhance the effect.

(1) Chemical Grain Refinement Technology: Mainstream Solutions and Parameter Control

Chemical grain refinement is achieved by adding master alloy refiners, among which Al–Ti–B series refiners are the most widely used. Newly developed Al–Ti–B–Re refiners effectively address the “poisoning” problem associated with traditional refiners.

Key Practical Parameters

Addition amount control:

The addition level should be adjusted according to alloy type. For conventional aluminum alloys, the recommended addition is 0.1%–0.3%. For recycled aluminum or alloys containing Zr or Si, the addition should be increased to 0.3%–0.5%. Excessive addition may lead to the formation of coarse TiAl₃particles.

Addition timing:

The refiner should be added after melt refining and 10–15 minutes before casting to ensure sufficient dissolution and to avoid adverse reactions with refining agents.

Temperature control:

The melt temperature during addition should be maintained at 700–720°C. Excessively high temperatures accelerate refiner burn-off, while excessively low temperatures result in incomplete dissolution.

Stirring process:

After addition, electromagnetic or mechanical stirring should be applied at 300–400 r/min for 3–5 minutes to ensure uniform distribution of nucleation particles.

Application of New Grain Refinement Technologies

Ultrasonically prepared Al–5Ti–B refiners reduce the average TiB₂ particle size from the conventional 2.13 μm to 0.65 μm, increasing the number of nucleation particles per unit volume by more than three times and significantly improving refinement efficiency.

In the production of aerospace-grade 7075 aluminum alloy, the use of this refiner increased ingot tensile strength by 15% and elongation by 20%.

(2) Physical Grain Refinement Technology: Auxiliary Methods and Process Optimization

Physical grain refinement methods regulate the solidification process through external energy fields. When used in combination with chemical refinement, they can further enhance grain refinement performance.

Electromagnetic stirring technology:

An electromagnetic field is applied in the mold region, with stirring speeds controlled at 150–250 r/min. This disrupts the growth of coarse grains, promotes uniform distribution of nucleation particles, and reduces centerline segregation.

Rapid solidification technology:

By adopting a “rapid quenching crystallization” process, the casting mold is immersed in low-temperature constant cooling water. The cooling rate is increased from the conventional 5–10 °C/s to 20–30 °C/s, resulting in significant grain refinement.

Vibration-assisted grain refinement:

Mechanical vibration is applied during casting at frequencies of 50–100 Hz and amplitudes of 0.1–0.3 mm, promoting bubble flotation and inclusion separation while simultaneously refining the grain structure.

III. Key Processes and Equipment Selection for Melt Purification Technology

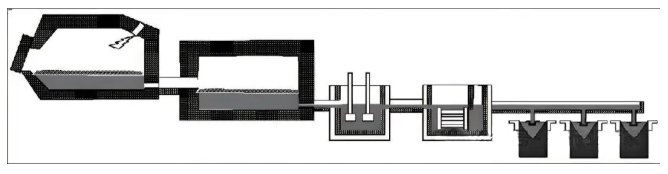

Melt purification technology follows the principles of “prevention first, removal as a supplement” and “slag removal before degassing.” Through a combination of refining, degassing, and filtration processes, gases and inclusions in the melt are effectively removed. At present, the most widely applied industrial solution is the online purification system, mainly consisting of rotary degassing units and ceramic foam filtration systems.

(1) Refining Processes: Controlling Melt Contamination at the Source

Refining processes are divided into in-furnace refining and online refining, both aimed at removing oxide inclusions and dissolved gases from the melt, thereby laying a solid foundation for subsequent purification steps.

In-Furnace Refining Technologies

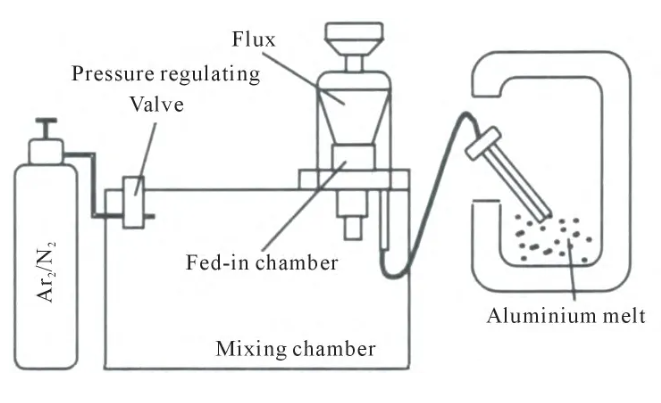

Flux refining:

Mixed fluxes such as Na₃AlF₆ and KCl are used, with an addition amount of 0.5%–1.0% of the melt mass. Refining is carried out at 720–740 °C with stirring for 15–20 minutes, removing most oxide inclusions and part of the dissolved hydrogen.

Gas refining:

High-purity argon (purity≥99.99%) is injected into the melt at a flow rate of 0.5–1.0 m³/h and a pressure of 0.2–0.3 MPa. As the bubbles rise, they adsorb dissolved gases and inclusions, achieving a hydrogen removal efficiency of 40%–60%.

Refining for recycled aluminum:

A specialized “dispersed non-chain refining” process is adopted, using a four-tube refining device. The refiner addition is 1.5 kg per ton of melt, with an injection rate of 1.0 kg/min and argon pressure of 0.25–0.35 MPa, reducing inclusion content by more than 43%.

Online Refining Technology

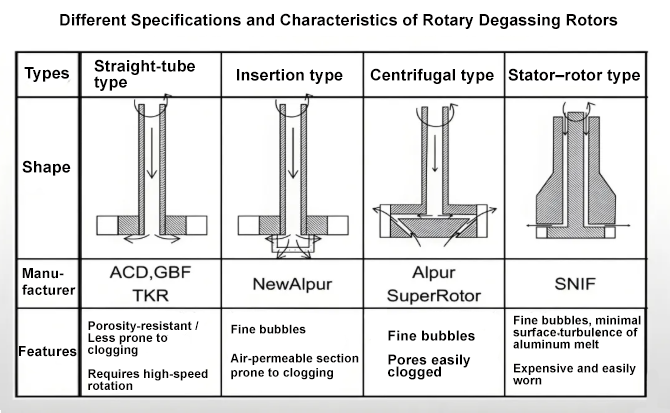

Online refining is performed synchronously with the casting process, avoiding secondary contamination of the melt. The primary equipment used is a rotary degassing unit.

(2) Filtration Processes: Deep Removal of Inclusions

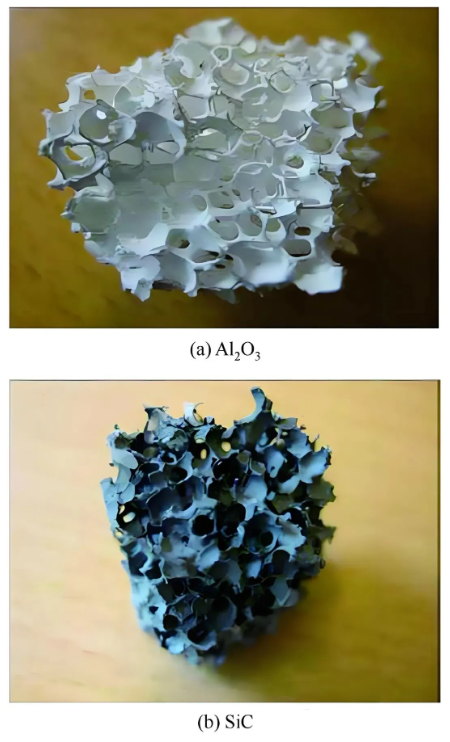

Filtration is a critical step in melt purification, intercepting inclusions through filter media. In industry, ceramic foam filters (CFFs) are predominantly used, accounting for over 95% of applications.

Selection of Filter Media

Material selection:

Al₂O₃or SiC ceramic foam filters are recommended, with a temperature resistance of≥ 1000°C and compressive strength of≥1.5 MPa, to prevent fracture and melt contamination at high temperatures.

Pore size selection:

For conventional aluminum alloys, 50–80 ppi filters are used. For high-end aluminum alloys (e.g., aerospace applications), 30–50 ppi filters are recommended. Recycled aluminum production requires dual-layer filtration (80 ppi + 50 ppi) to ensure effective inclusion removal.

Size selection:

The filter area should be adjusted according to the casting speed, typically 0.1–0.3 m², ensuring that the melt flow velocity is controlled within 0.5–1.0 m/min to prevent filtration failure caused by excessive flow rates.

Optimization of Filtration Processes

Preheating treatment:

Filters must be preheated to 600–700°C before use to prevent thermal shock when contacted by molten aluminum, which could otherwise generate new inclusions.

Installation method:

Horizontal installation is recommended, with the pressure differential across the filter controlled at 0.02–0.05 MPa, ensuring uniform melt flow through the filter medium.

Replacement interval:

Filters should be replaced after every 50–80 tons of molten aluminum processed, or immediately when the pressure differential exceeds 0.08 MPa, to prevent clogging and inclusion accumulation.

(3) Emerging Purification Technologies: Highly Efficient Synergistic Solutions

Three-dimensional multi-tube degassing technology:

A degassing device with multiple tubes arranged in a three-dimensional configuration is used, with each tube equipped with φ5 mm degassing holes. At an argon pressure of 0.20–0.25 MPa, the hydrogen content in the melt can be reduced to below 0.12 ml/100 g Al, meeting the requirements for high-end cast products.

Ultrasonic purification technology:

Ultrasonic waves are applied before and after filtration at frequencies of 20–40 kHz and power levels of 500–1000 W. This breaks up fine inclusion agglomerates and promotes the attachment and flotation of bubbles and inclusions, further enhancing purification efficiency.

Online slag monitoring technology:

Laser-based slag detection systems are used to monitor inclusion content in the melt in real time. When the inclusion level exceeds 0.03%, refining and filtration parameters are automatically adjusted, ensuring stable melt cleanliness.

IV. Key Operational Control Points and Common Problem-Solving Strategies

(1) Core Parameter Control Guidelines

Temperature control:

Melting temperature: 730–750°C; refining temperature: 720–740°C; casting temperature: 690–710°C.

Temperature fluctuations at each stage should not exceed±10°C.

Time control:

Melt holding time: 20–30 minutes; stirring time after grain refiner addition: 3–5 minutes; degassing time: 15–20 minutes.

Excessively long melt residence times should be avoided to prevent secondary contamination.

Purity control:

Argon purity≥99.999%; nitrogen purity≥99.995%; refining agent purity≥98%; ceramic filter porosity≥80%.

Inspection and monitoring:

For each heat, measure hydrogen content (≤0.15 ml/100 g Al) and inclusion content in the melt.

For each batch, test ingot grain size and mechanical properties.

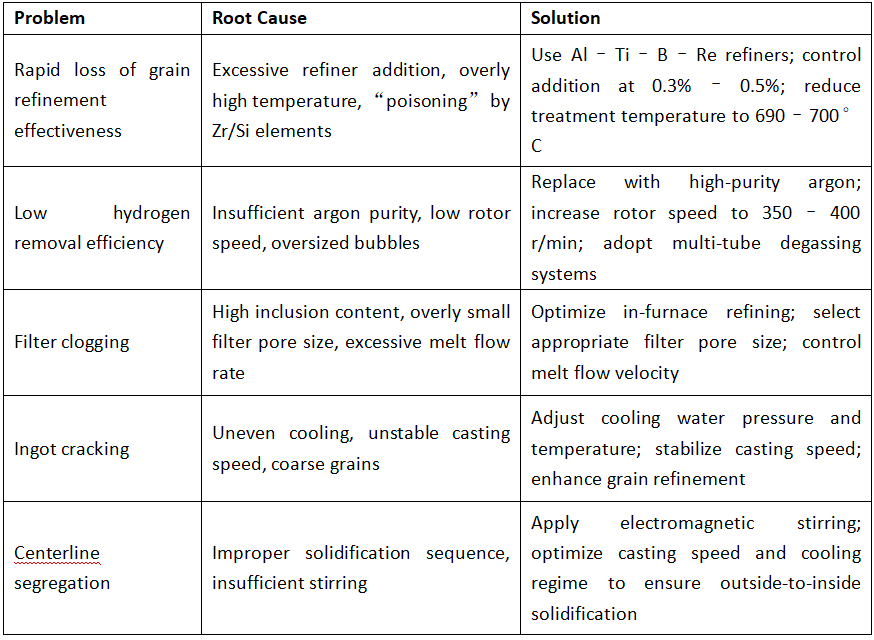

(2) Common Problems and Solutions

(3) Key Points for Equipment Maintenance and Servicing

Melting furnace:

Regularly clean the furnace lining; inspect furnace sealing monthly to prevent air leakage.

Check heating element performance quarterly to ensure uniform heating.

Degassing equipment:

Clean graphite rotors and nozzles weekly; inspect rotor wear monthly; replace rotors every 6–12 months.

Filtration system:

Clean filter boxes after each casting operation; check sealing during filter replacement to prevent melt short-circuiting.

Inspect filter installation accuracy monthly.

Inspection equipment:

Calibrate hydrogen analyzers and slag/inclusion detectors daily; check probe sensitivity weekly to ensure accurate measurements.

Conclusion

The combined application of grain refinement and melt purification technologies is the key approach to eliminating the five major defects in aluminum deep-processing casting. Its essence lies in improving melt quality and solidification microstructure at the source through precise process parameter control, rational equipment selection, and effective synergistic operation.

With the implementation of updated national standards and the continuously increasing quality demands of high-end manufacturing, this combined technology is evolving toward intelligent, high-efficiency, and green development pathways—such as AI-based visual defect detection, real-time process parameter optimization, and the development and application of new environmentally friendly refiners and purification agents.

In practical applications, enterprises should tailor process parameters to their specific product types, raw material characteristics, and equipment conditions. By integrating operational experience, strengthening process monitoring, and reinforcing equipment maintenance, defect rates can be effectively reduced while product quality and market competitiveness are enhanced. Looking ahead, continuous technological innovation will drive aluminum deep-processing casting toward “zero-defect” production, providing a solid foundation for the expanded use of aluminum alloys in more high-end application fields.

Post time: Feb-03-2026