As a major hazardous solid waste generated in the aluminum industry, aluminum dross requires proper treatment to achieve effective resource recovery and environmental protection. This paper conducts an in-depth analysis of the advantages and disadvantages of different aluminum dross treatment methods, including pyrometallurgical, hydrometallurgical, physical separation, and other emerging techniques. Pyrometallurgical methods provide high recovery rates but involve high energy consumption and hazardous residues; hydrometallurgical methods effectively treat harmful substances but face challenges such as long process duration and wastewater disposal; physical separation is simple and low-cost, but its separation efficiency is limited by feedstock composition; emerging methods show promising potential yet encounter technical and economic challenges. Through a comprehensive comparison, this paper aims to provide a scientific basis for selecting and optimizing aluminum dross treatment technologies, promoting the green and sustainable development of the aluminum industry.

1. Introduction

With the rapid development of the global aluminum industry, the generation of aluminum dross has been increasing year by year. Aluminum dross is a solid waste produced during aluminum smelting and processing. It has a complex composition containing metallic aluminum, alumina, aluminum nitride, aluminum carbide, soluble salts, and fluorides. Improper disposal not only leads to a significant waste of aluminum resources but also causes severe pollution to soil, water, and air, posing risks to human health. Therefore, selecting appropriate treatment methods to achieve harmless and resource-efficient utilization of aluminum dross has become a key issue for the sustainable development of the aluminum industry.

Currently, numerous aluminum dross treatment technologies exist, each with distinct principles, applicable conditions, and advantages and disadvantages. Understanding and comparing these technologies help enterprises and researchers select the most suitable processes based on actual conditions, improve treatment efficiency, reduce costs, and minimize environmental impact. This paper systematically reviews and analyzes the common aluminum dross treatment methods to provide reference for further technological development.

2. Sources and Composition of Aluminum Dross

2.1 Sources

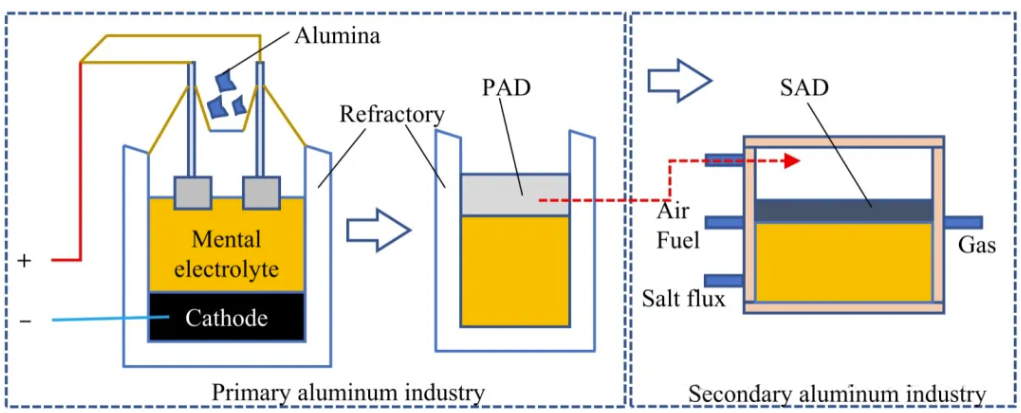

Aluminum dross mainly originates from primary aluminum production, aluminum processing, and secondary aluminum recycling. During the electrolytic aluminum process, a layer of scum forms on the surface of the molten aluminum — one of the main sources of aluminum dross. It is also generated during aluminum melting and casting processes. In secondary aluminum production, aluminum dross is produced when scrap aluminum is remelted and recovered. Statistics show that for every ton of aluminum produced, approximately 100–150 kg of aluminum dross is generated. As aluminum output continues to increase, aluminum dross generation is also on the rise.

2.2 Composition

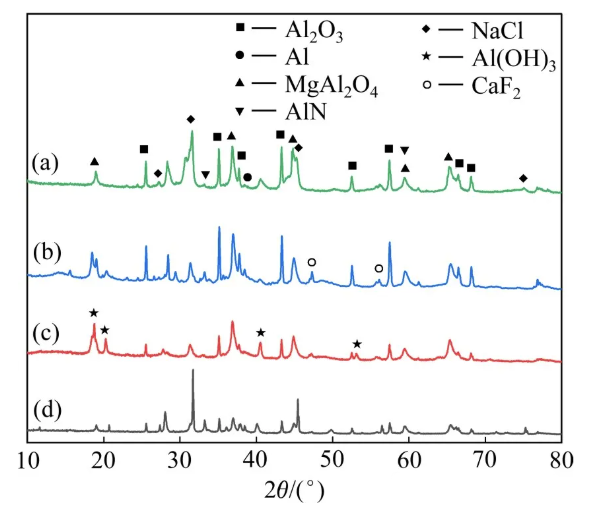

The composition of aluminum dross is complex and varies significantly depending on its source and production process. Primary aluminum dross (generated during primary aluminum production) contains a higher metallic aluminum content, typically 15%–70%, mainly composed of metallic aluminum and alumina, and appears gray-white, also known as “white dross.” Secondary aluminum dross — the residue after extracting metallic aluminum from primary dross — contains less than 10% metallic aluminum and is more complex in composition. It typically includes flux residues (over 10%), oxides, aluminum nitride (15%–30 wt%), and other compounds. Moreover, aluminum dross may also contain impurities such as iron, silicon, copper, manganese, magnesium, zinc, titanium, and various salts such as fluorides and chlorides. These components make aluminum dross difficult to treat, while also giving it recycling value.

3. Common Aluminum Dross Treatment Methods and Their Advantages and Disadvantages

3.1 Pyrometallurgical Methods

3.1.1 Stirring (Frying) Method

The stirring or “frying” method is a relatively primitive aluminum dross treatment technique. Its principle is based on the difference in wettability between molten aluminum and other materials in the dross. During the process, certain fluxes (such as zinc chloride) are added to promote the separation of aluminum from impurities. This method is simple and low-cost, still used in small aluminum processing plants. However, it has significant drawbacks: large amounts of fume and dust are generated, including harmful substances such as HCl (from the reaction of ZnCl₂ with moisture), causing severe environmental pollution. In addition, it requires skilled labor, involves high labor intensity, and the aluminum recovery rate is limited. The treated residue still contains aluminum, preventing efficient resource recovery.

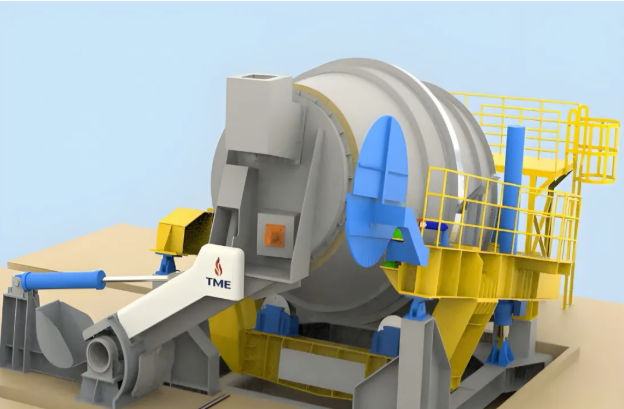

3.1.2 Tilting Rotary Furnace Method

The tilting rotary furnace method employs a cylindrical furnace with a specific inclination angle and mechanical transmission. Aluminum dross is repeatedly agitated in the rotating furnace; as temperature increases, molten aluminum settles at the bottom under gravity and accumulates for recovery. This method has large processing capacity, high mechanization, and better environmental performance, making it suitable for large-scale operations. However, the use of molten salts poses environmental and safety risks, including the emission of toxic gases, requiring strict safety measures. It also generates a large amount of salt cake, whose disposal is challenging and costly.

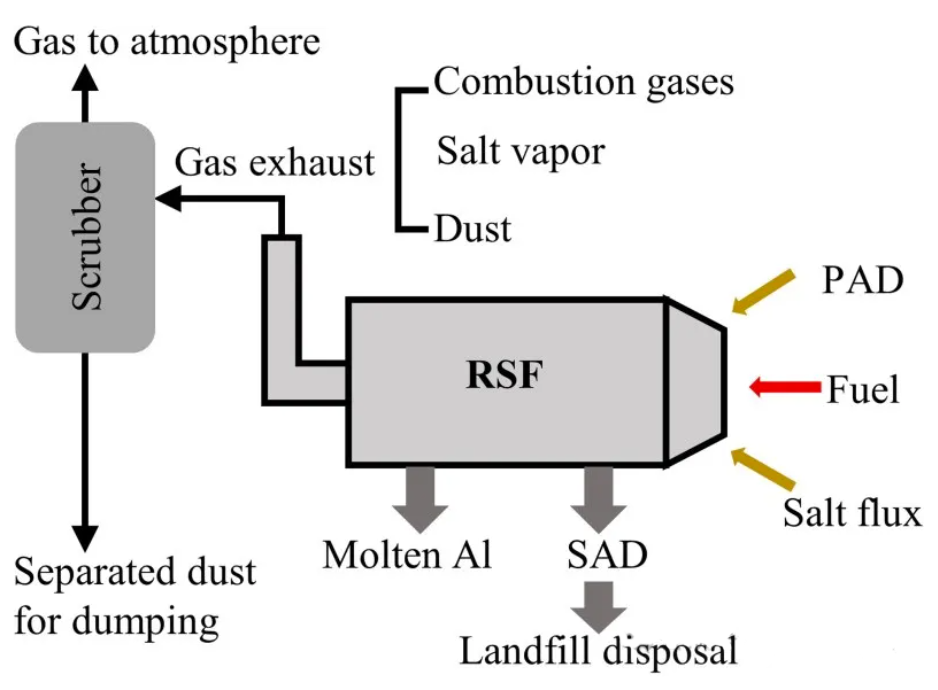

3.1.3 Rotary Melting Furnace Method

The rotary melting furnace process includes feeding, heating, aluminum collection, and slag discharge. It heats rapidly, reducing the emission of organic gases; fumes can be captured and treated for reuse. The degree of mechanization is high, and the working environment is relatively good. However, its metal recovery rate is around 93%, which is lower than some other pyrometallurgical methods such as the frying method. In addition, the residual aluminum dross requires further processing, increasing operational complexity and cost.

3.1.4 Plasma Arc Method

The plasma arc method uses a high-temperature plasma formed by ionization to melt aluminum dross, separating metallic aluminum and alumina slag. Typically, fluxes such as calcium oxide are added to form two valuable products: metallic aluminum and calcium aluminate. This method provides high recovery efficiency, high product value, and excellent resource utilization. However, it requires advanced equipment, high investment, and complex operation, making it currently suitable only for high-end applications demanding high recovery and purity.

3.2 Hydrometallurgical Methods

3.2.1 Acid Leaching

Acid leaching uses acidic solutions to react with metals, oxides, carbides, and nitrides in aluminum dross, forming soluble salts to recover aluminum and other valuable elements. Under specific conditions (e.g., 4 mol/L HCl, 100°C, 120 min), alumina leaching efficiency can reach up to 71%. The process is simple and does not require complex equipment. However, alumina dissolution reduces product purity, and the method generates large amounts of acidic wastewater containing heavy metal ions. Without proper treatment, this wastewater severely pollutes the environment. Neutralization, precipitation, and filtration treatments increase cost and complexity.

3.2.2 Alkali Leaching

Alkali leaching uses alkaline solutions to react with aluminum dross components for separation and recovery. Compared with acid leaching, it effectively removes impurities and yields products of higher purity. Nevertheless, alkali consumption is high, raising costs. Alkaline wastewater also requires proper disposal to avoid environmental harm. Due to high treatment costs and waste management challenges, its industrial application remains limited.

3.3 Physical Separation Methods

3.3.1 Gravity Separation

Gravity separation utilizes differences in density among aluminum dross components under gravitational force. It is simple, low-cost, and chemical-free, making it environmentally friendly. However, due to small density differences among major components, the separation efficiency is limited, preventing high recovery and purity.

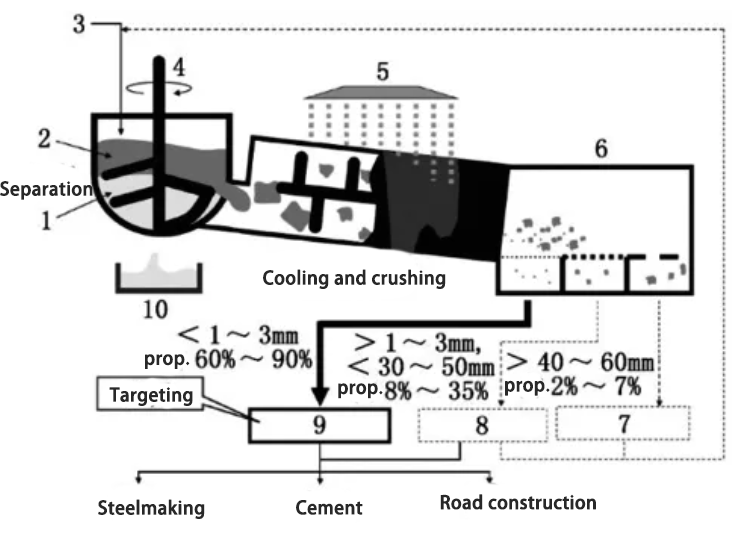

3.3.2 Grinding and Screening

Grinding and screening involve crushing aluminum dross and separating it by particle size. The method is mature and uses simple equipment, but since the dross components have different hardness and brittleness, crushing results are uneven, affecting efficiency. The process also produces dust pollution, and device performance varies widely across applications.

3.3.3 Flotation

Flotation employs reagents to exploit surface property differences between dross components. Under suitable conditions, flotation can effectively separate valuable materials. However, it requires fine particle sizes, necessitating pre-treatment and increasing costs. The process consumes large amounts of water, and improper reagent use or wastewater discharge can pose environmental risks.

3.3.4 Centrifugal Separation

Centrifugal separation uses centrifugal force to separate materials based on different trajectories of components with different densities. The process is simple and relatively efficient, but its technical maturity is low. For complex aluminum dross compositions, the separation efficiency remains limited, restricting widespread adoption.

3.4 Other Treatment Methods

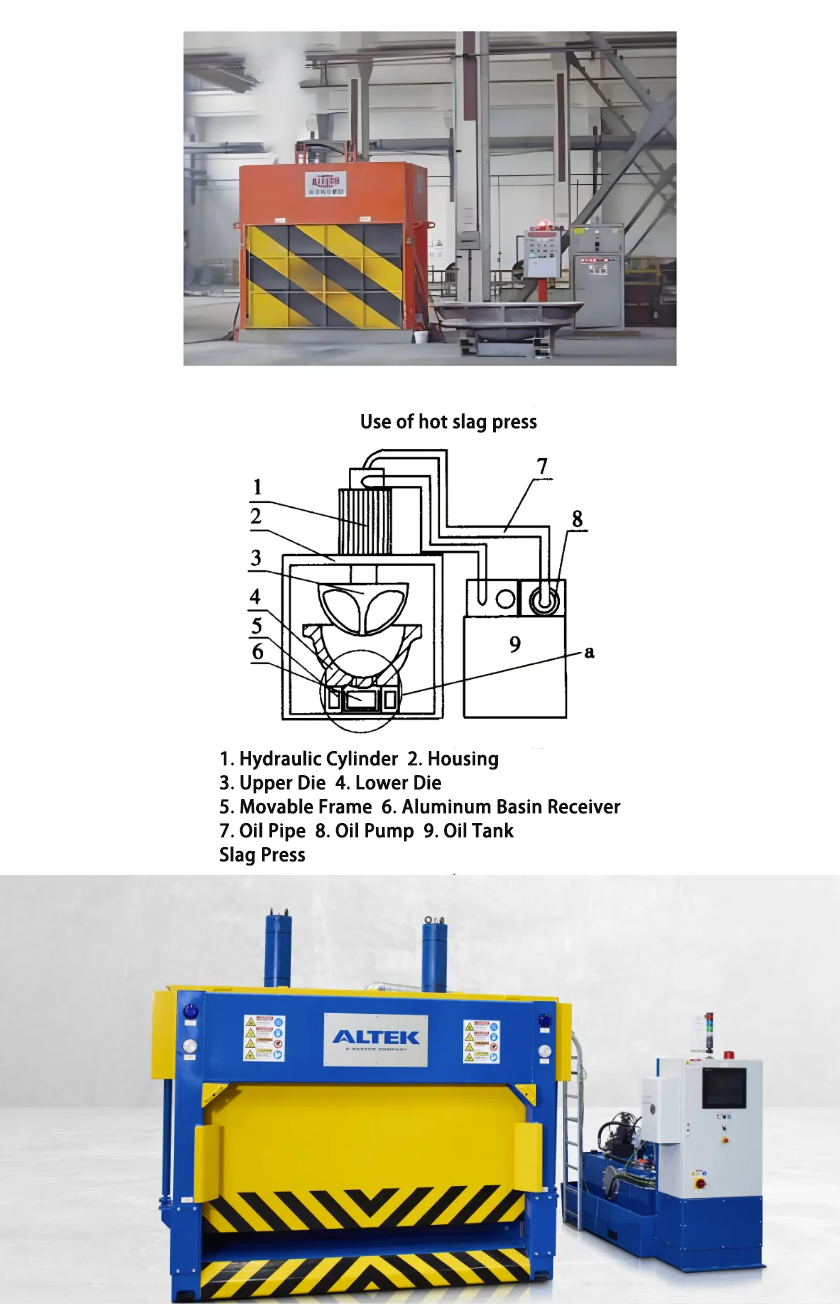

3.4.1 Press Extraction Method

The press extraction method involves feeding hot aluminum dross into a filter press, applying static or dynamic pressure to squeeze out molten aluminum. This technique does not require pre-cooling, and the equipment is simple, low-cost, and easy to operate and maintain, with a short working cycle and high automation. However, in China, its applicability is poor due to compositional and process differences, limiting its industrial use.

3.4.2 Electrostatic Separation

Electrostatic separation utilizes electrical property differences among aluminum dross components to achieve separation under an electric field. This process is pollution-free and aligns with environmental trends, showing strong potential. However, it requires a stable and substantial power supply, increasing operational costs and limiting its practicality where electricity is expensive or unstable.

4. Comprehensive Comparison and Analysis

4.1 Comparison of Treatment Performance

Regarding treatment performance, the plasma arc and rotary furnace methods achieve higher aluminum recovery, though the latter still produces residual dross requiring further treatment. Acid and alkali leaching effectively remove harmful substances but struggle with product purity and waste management. Among physical methods, flotation performs well under optimized conditions but is sensitive to feedstock composition. Overall, no single method excels universally; process selection should be based on dross composition and target outcomes.

4.2 Cost Comparison

Cost is a key factor in method selection. The frying method is inexpensive but polluting and inefficient. The tilting rotary and rotary melting furnaces require large investment and high operating costs; plasma arc is even more expensive. Acid and alkali leaching involve not only reagent and equipment costs but also costly wastewater treatment. Physical methods such as gravity separation and screening are low-cost but less effective; flotation and centrifugal separation are more costly and complex. The press extraction method is low-investment but poorly adaptable domestically. Electrostatic separation consumes significant electricity, further raising costs.

4.3 Environmental Impact Comparison

From an environmental standpoint, the frying and tilting rotary methods emit large amounts of toxic gases and dust. The rotary melting and plasma arc furnaces offer improved emission control but still pose certain risks. Acid and alkali leaching generate hazardous wastewater; gravity separation and grinding produce dust; flotation consumes water and reagents; centrifugal separation is relatively clean but technologically immature. Press extraction and electrostatic methods are more environmentally friendly, though the latter’s high power demand indirectly increases carbon emissions.

5. Case Studies

5.1 Large Aluminum Company Using Rotary Melting Furnace

A large aluminum producer adopted the rotary melting furnace method for aluminum dross treatment. Handling large daily dross output, the company invested in advanced rotary furnace equipment, achieving high mechanization and processing efficiency. However, despite decent recovery rates, further improvement was needed, as residual dross required additional processing. The maintenance cost was high, and regular servicing was essential. To address these issues, the company optimized operating conditions, enhanced residual dross utilization, and collaborated with suppliers to improve equipment reliability.

5.2 Small Aluminum Processing Enterprise Using Acid Leaching

A small aluminum enterprise chose acid leaching due to limited capital and technical capacity. The method required low investment and met early production needs. However, over time, its drawbacks emerged — large volumes of acidic wastewater were difficult to treat, and disposal facilities required high investment. The company faced pollution issues and declining product quality due to low purity. Consequently, it began seeking technical upgrades, exploring advanced acid leaching and wastewater treatment solutions through collaboration with research institutions.

6. Conclusions and Prospects

6.1 Conclusions

Each aluminum dross treatment method has its own advantages and disadvantages. Pyrometallurgical methods offer high metal recovery but are energy-intensive and polluting. Hydrometallurgical methods effectively handle harmful substances but face issues of product purity and wastewater treatment. Physical separation is simple and low-cost but limited by feedstock composition. Other methods, such as press extraction and electrostatic separation, have niche applications but also inherent constraints. Currently, no single technique meets the combined requirements of efficiency, environmental protection, and low cost.

6.2 Prospects

Future aluminum dross treatment technologies should move toward diversification, greenness, and high efficiency. A promising direction is combining multiple methods to maximize their advantages — for instance, using physical separation for pre-treatment, followed by pyrometallurgical or hydrometallurgical processes for deep recovery. Moreover, innovative technologies such as biological or microwave-assisted treatment, with low energy consumption and minimal pollution, show great potential. Attention should also be given to resource recycling within the process, converting aluminum dross components into high-value-added products, thereby enhancing both economic and environmental benefits and promoting the sustainable development of the aluminum industry.

Post time: Oct-25-2025