In the production and processing of aluminum foil and composite films, the winding stage is the final step and also the most prone to quality issues. Typical defects include circumferential surface protrusions (“veins”) and uneven roll ends such as telescoping or stepped layers.

These defects not only affect product appearance but can also cause serious issues in subsequent processing and in the final performance. This article provides a systematic analysis covering consequences, definitions, causes, and process optimization measures.

I. Quality Consequences: Impact on Appearance, Processing, and Performance

1.1 Material Scrap and Increased Costs

Severe veins can cause local plastic deformation of the aluminum foil, making it impossible to restore flatness after unwinding. Entire rolls may become scrapped, especially in high-value products such as battery foil or double-zero foil.

1.2 Increased Risk of Downstream Machine Downtime

Uneven roll ends may lead to web wandering, tension fluctuations, or even web breakage during coating, slitting, or laminating. According to industry statistics from Soft Packaging Processing Technology, 30%–40% of slitting breaks are related to poor parent-roll winding quality.

1.3 Performance Risks

At vein locations, local overstress may induce microcracks or pinholes, reducing barrier properties, increasing water–oxygen transmission, and weakening mechanical performance.

II. Defect Definitions: Clear Identification of Problem Types

2.1 Circumferential Veins (Veins / Ridges)

Appearance: continuous linear protrusions along the circumferential direction of the roll, with a clearly detectable hardness and height difference.

Essence: localized thickness accumulation or excessive winding tension causes interlayer pressure to exceed the material yield limit or friction limit, forming a concentrated stress band.

2.2 Uneven Roll Ends (Telescoping / Dished Roll)

Appearance: roll ends become uneven, showing inward/outward slippage or a tower-like shape.

Essence: insufficient interlayer friction during winding fails to resist lateral forces or internal stresses, resulting in interlayer sliding.

III. Cause Analysis: Combined Effects of Material, Tension, and Airflow

3.1 Causes of Circumferential Veins

Thickness Tolerance Accumulation (Primary Cause)

Aluminum foil cannot achieve perfect cross-direction uniformity. A slight over-thickness at a fixed position will accumulate over thousands of layers, creating a significant diameter difference that produces circumferential stress concentration and eventually veins. In high-speed winding, even a 1 μm deviation may trigger defects.

Excessive Winding Tension

Overly high initial tension tightens the inner layers excessively. As roll diameter increases, the compressive force on the inner layers grows exponentially, resulting in bulges or ridge lines.

3.2 Causes of Uneven Roll Ends

Improper Taper Tension Setting

If the outer-layer tension is higher than the inner-layer tension (reverse taper), outer layers compress the inner layers, causing outward slippage and forming telescoping ends.

Air Entrainment

At winding speeds above approximately 300 m/min, air easily enters between layers, significantly reducing interlayer friction and increasing the likelihood of lateral sliding.

Mechanical Precision Issues

Misalignment between winding and guide rolls, excessive shaft runout, or poor core end quality can all produce uneven roll ends.

IV. Process Optimization: Targeted Adjustments and Mechanical Accuracy Control

4.1 Solutions for Circumferential Veins

A. Introduce Oscillation Mechanism

Cross-machine-direction oscillation disperses thickness variations across the roll, preventing accumulation at a single point. Typical oscillation amplitude is ±5–20 mm, with frequency adjusted dynamically with roll growth.

B. Optimize Contact Roller Pressure

A properly selected lay-on roller helps expel trapped air and absorb minor thickness variations. A rubber roller with Shore A hardness 60–70 is recommended to avoid intensifying vein formation.

C. Improve Incoming Material Shape

Upstream gauge profile control (AVC) should be used to reduce thickness variations and cross-direction high spots.

4.2 Solutions for Uneven Roll Ends

A. Proper Taper Tension Settings

Tension should decrease progressively as roll diameter increases. A tension reduction of 15%–25% is typically recommended to avoid outer-layer compression and interlayer slippage.

B. Precise Control of Contact Roller Pressure

Appropriate pressure improves air removal and increases interlayer friction. A pressure taper can be used: slightly higher pressure at the start, then adjusted with roll growth to maintain stable unit-area pressure.

C. Improve Mechanical Accuracy

This includes calibrating roll parallelism (within 0.05 mm/m), checking dynamic balance, and ensuring core end quality.

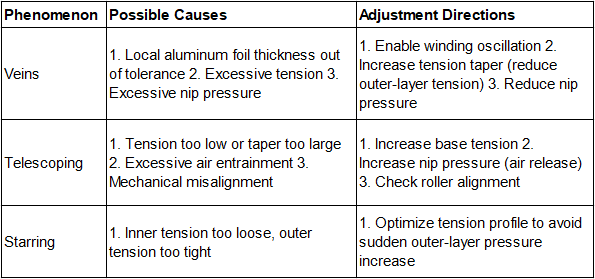

4.3 Troubleshooting Table

Summary

Veins and uneven roll ends in aluminum foil winding arise from the interaction between thickness accumulation and imbalanced internal winding stresses. Core technical actions include: dispersing thickness deviations through oscillation, balancing internal stresses through proper taper tension, enhancing interlayer friction through effective air removal via the contact roller, and maintaining mechanical precision for stable roll formation.

For practical troubleshooting, it is recommended to first verify the oscillation function and then review tension history curves to detect abnormalities or improper taper settings.

Post time: Dec-12-2025