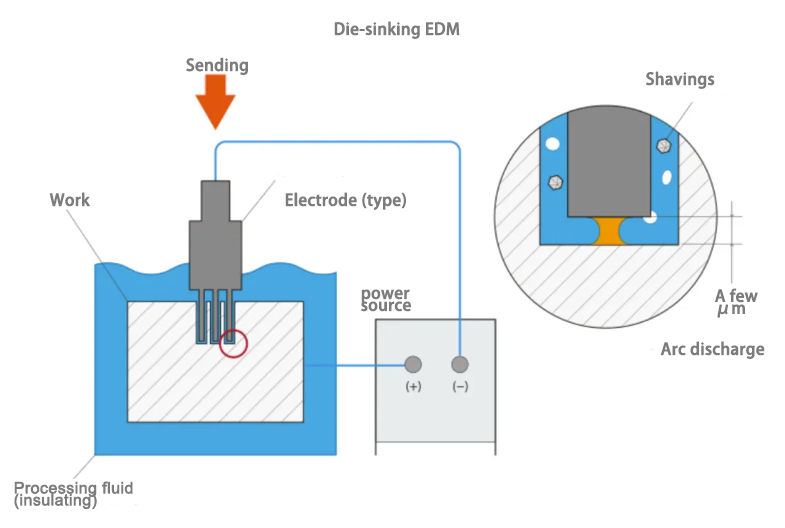

Electrical Discharge Machining (EDM) is a processing method that converts electrical energy into thermal energy to melt metal. It is discharged into the gap of several micrometers between the workpiece and the tool (electrode) and gently scrapes the metal under heat and impact exceeding 6000°C. By immersing the workpiece in an insulating working fluid and generating tens of thousands of sparks (arc discharges) per second, a machining accuracy of 1 micron can be achieved on the surface of the workpiece.

EDM:

Electrical Discharge Machining is a method that uses electrodes to utilize spark discharge energy to melt and process the metal surface of an object.

It features high-precision machining of complex shapes regardless of material hardness and is widely used mainly in the mold manufacturing field.

There are three machining methods in EDM: die-sinking EDM, wire-cut EDM, and small-hole EDM.

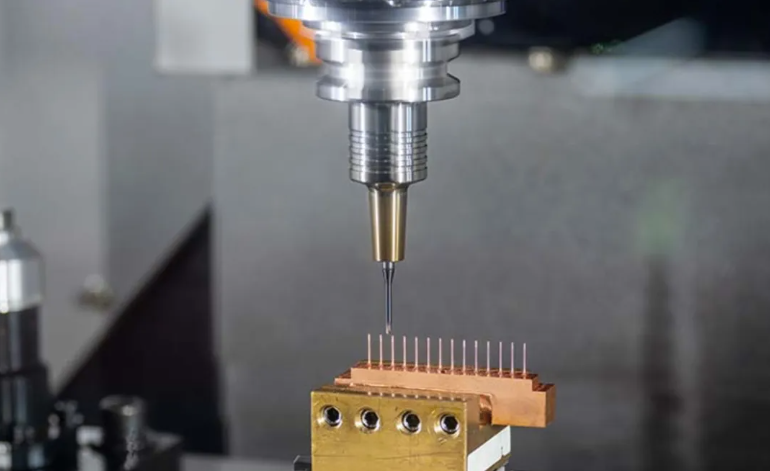

Die-sinking EDM: Uses a pre-shaped mold electrode to transfer the shape of the mold.

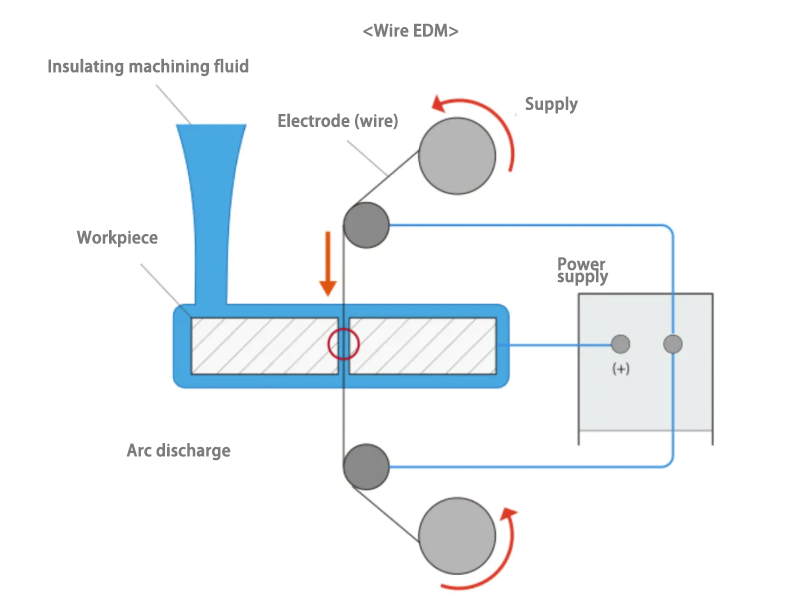

Wire-cut EDM (WEDM): Uses a thin wire-shaped electrode to cut metal like a wire saw.

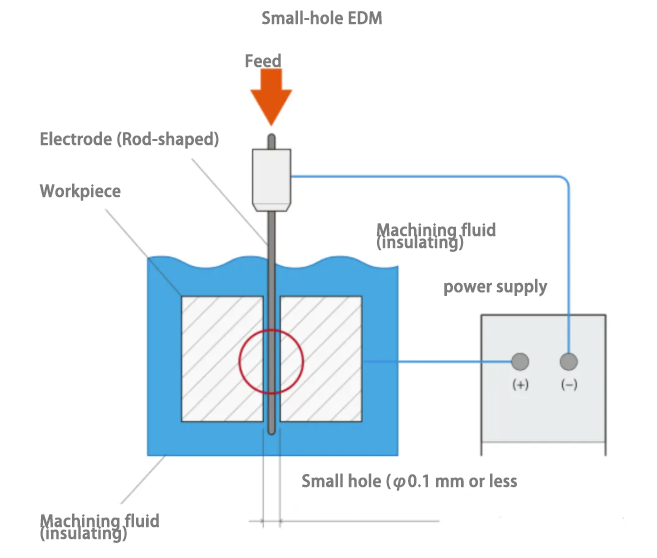

Small-hole EDM: Uses a rod-shaped electrode to drill holes in metal.

In both processes, the workpiece is immersed in an insulating working fluid (deionized water or petroleum-based liquid), and electric current flows through the workpiece side (+) and the electrode side (−). (Depending on the working fluid, machining accuracy, productivity, and cost vary.)

There is a gap of several micrometers between the workpiece and the electrode, and machining is performed without contact. The “electrode” used as a mold is made of inexpensive and soft materials such as commercially available copper and graphite.

By using an electrode with a pre-shaped mold, the mold’s shape can be transferred. The mold (electrode) is brought close to the workpiece in the working fluid, pressed against it, and then discharged. The NC control of the electrode enables complex three-dimensional machining.

During machining, an “NC Die-sinking EDM Machine” is used.

There are also machines such as the “Creation EDM Machine”, which freely moves standard product electrode rods to form various shapes, and the “Graphite Processing Machine”, used for machining graphite electrodes.

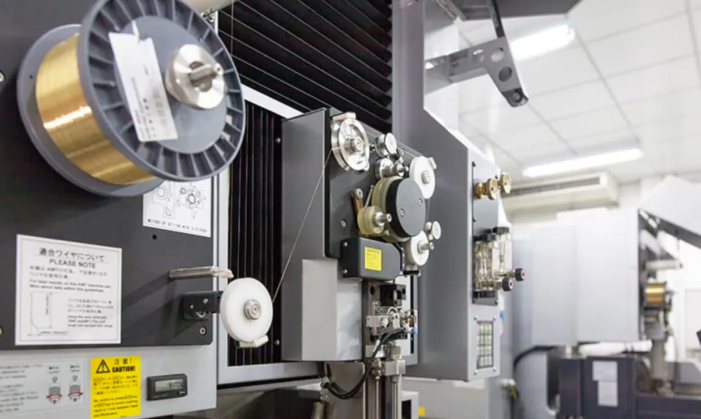

A thin wire-shaped electrode is used like a wire saw to cut metal. The wire (electrode) is brought close to the workpiece in the working fluid, pressed against it, and then discharged.

Through NC control of the electrode, fine two-dimensional contour machining can be performed.

The “electrode” used as the wire is copper or tungsten with a diameter of about 0.1 mm, which cuts the workpiece while being wound around it under tension.

Wire-cut Electrical Discharge Machining is also called WEDM (Wire Electrical Discharge Machining).

During machining, a “Wire-cut (NC Wire-cut)” machine is used.

Small-hole EDM Machine

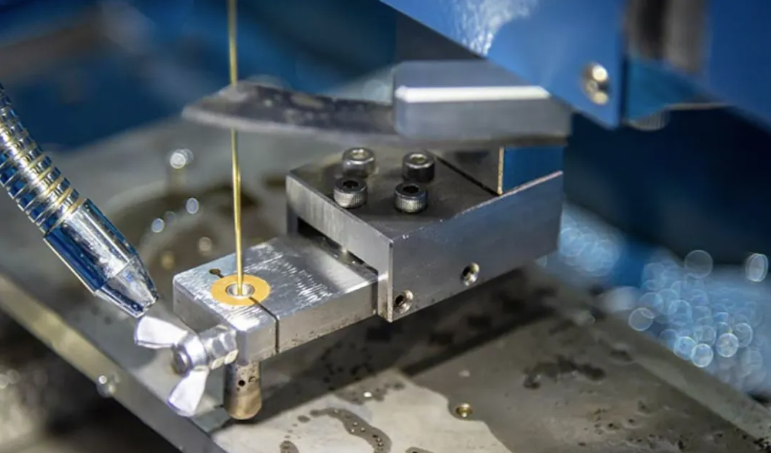

Uses a rod-shaped electrode to drill holes in metal. In the working fluid, tools (electrodes) such as copper or brass are pressed against and discharged from the workpiece.

It can drill fine and deep holes of φ0.1 mm or smaller, which conventional drilling cannot achieve, and is actively used to machine small holes such as exhaust holes in molds and precision nozzles. (Compared with drilling, it features a lower burr generation rate.)

During machining, an “NC Small-hole EDM Machine” is used.

About “Plasma Machining” Applied from Discharge Machining (EDM)

“Plasma Machining” is a type of discharge machining. It is a processing method in which the energy generated by discharge (a plasma jet) is injected through a nozzle to cut a workpiece. Since it can even process non-conductive materials, it is used for cutting thick plates such as steel plates, alloys, and stainless steel.

Because it has lower operating costs and provides better cutting surface accuracy than laser machining, it is often used as a replacement for gas cutting. In addition, it can cut thick plates of 25 mm or more, which is difficult for a turret punch press.

For plasma processing, a “plasma processor” is used.

What is “Electrochemical Machining (ECM)” similar to Electrical Discharge Machining (EDM)?

“Electrochemical Machining” is a process similar to Electrical Discharge Machining.

Electrochemical machining is a processing method in which metal is chemically “dissolved” by applying an alkaline electrolyte into the gap of a few micrometers between the workpiece and the tool (electrode).

Like EDM, any conductive metal can be processed. It is also used for micro-machining and deburring of “difficult-to-cut materials,” which were previously hard to machine.

There are machining methods such as “die-sinking electrochemical machining” and “wire electrochemical machining.”

Since no heat is generated, surface cracking is less likely to occur compared to EDM, and the machining speed is also faster.

Electrochemical machining is also called ECM (Electro Chemical Machining), and the machine used for it is an “NC Electrochemical Machining Tool.”

Post time: Oct-25-2025