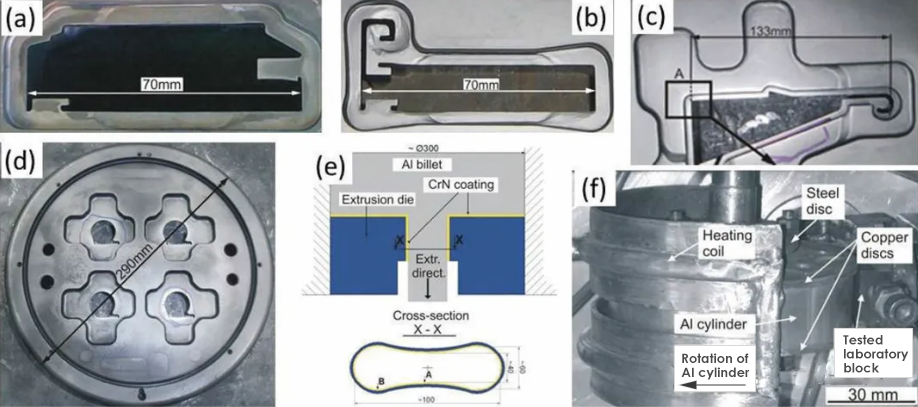

Aluminum extrusion dies are typically made of H13 tool steel and are subjected to high thermal, mechanical, frictional, and chemical loads during operation. The temperature on the die bearing surface can reach up to 600 °C, the normal contact pressure is usually below 30 MPa, and the sliding speed can reach 100 m/min. Meanwhile, the die also reacts with hot aluminum. These loads depend on various extrusion conditions—such as billet temperature and chemical composition, extrusion ratio, ram speed, die design, material flow, and the profile’s shape and dimensions. These complex interactions can lead to die damage, including wear, cracking, fracture, and plastic deformation. Such damage affects the surface finish and dimensional accuracy of extruded profiles, ultimately determining die service life.

To extend the service life of the die bearing surface, nitriding is commonly used for surface hardening. However, dies coated with CrN (chromium nitride) have shown superior hardness and wear resistance, making CrN coating a promising alternative hardening method for hot extrusion applications.

Service Life and Wear Analysis of Extrusion Dies

The acceptable service life of a nitrided die—expressed as the total length of extruded profiles—is typically at least 50,000 m. In contrast, dies coated with CrN by the PVD process can reach service lives of 200,000 m or more. Die wear mainly relates to cracking at the sharp edges of the bearing surface. Comparing two dies under similar extrusion ratios, ram speeds, and other key process parameters, the CrN-coated die exhibits a significantly longer life. The length of the adhesive and sliding regions on the bearing surface depends primarily on contact pressure, which decreases sharply near the die exit edge.

When the stiffness and toughness near the exit edge are reduced, two types of damage tend to occur:

Excessive nitriding can cause grain boundary separation at the exit edge, leading to local spalling;

Nitrided layer detachment may occur within 0.2–0.6 mm from the die exit edge.

These damages result from high normal and frictional stresses combined with reduced stiffness and toughness due to over-nitriding. Cracks then initiate and propagate, leading to significant adhesive material removal at the edge. Studies indicate that slightly extending the bearing surface length or avoiding over-nitriding near the exit edge can effectively prolong die service life.

Conclusions and Optimization Directions

(i) The service life of CrN-coated dies in aluminum hot extrusion is significantly longer than that of traditional nitrided dies, thereby improving the overall economic efficiency of the extrusion process;

(ii) Wear patterns and their occurrence times obtained from laboratory tests on nitrided specimens can be used to infer the primary contact pressures on industrial die surfaces. Adhesive spalling, cracking, and surface protrusion expansion are typical wear phenomena;

(iii) Die life can be further extended by improving die design to reduce strain rate and contact pressure along the bearing surface, avoiding edge over-nitriding, enhancing the microstructural quality of the nitrided layer, and selecting an appropriate bearing surface length for each die and extrusion condition. Additionally, optimizing die cavity layout, surface treatment, and maintenance practices is beneficial;

(iv) Proper die design prior to surface treatment and consistent die maintenance are key factors in fully utilizing the superior wear resistance and extended service life of CrN-coated dies compared with nitrided ones.

Post time: Oct-24-2025