Modern aluminum extrusion plants involve hundreds of variables, starting from billet selection and extending throughout the entire production process. The casting stage alone includes many factors, such as chemical composition. For example, alloy 6005A is made of aluminum with eight primary elements—silicon, iron, copper, manganese, magnesium, chromium, zinc, and titanium—along with trace amounts of other elements. Additional variables in billet production include scrap loading, melting, impurity removal, grain refinement, degassing, processing speed, solidification, hot cracking, die temperature control, lubrication, homogenization, stress relief, and sawing. Since most extrusion plants do not produce billets in-house, or even within the same facility, when building machine learning models it may be sufficient to focus only on the composition of the received billets rather than the details of billet production.

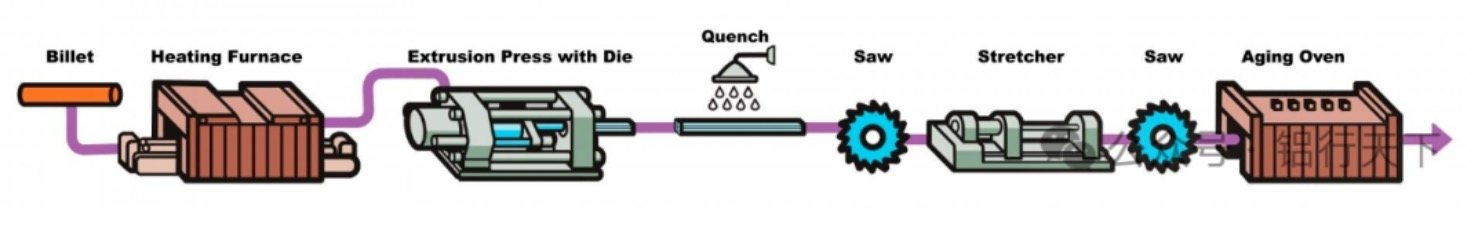

A typical process in an extrusion shop starts with selecting high-quality billets and continues with aging and final processing

During extrusion, billets are cut and heated before being loaded into the press for forming. The profiles are immediately quenched, then stretched, sawn, and aged according to customer requirements. Each stage introduces additional variables. In heating, the key factors include billet diameter and length, alloy type, heating rate, initial temperature, temperature gradient, heating efficiency, and energy consumption. Throughout the extrusion process, temperature is always the most critical factor: billet temperature, die temperature, and exit temperature determine the flow of the metal and the final properties. Other important factors include extrusion speed, extrusion ratio, and applied pressure.

Engineers and metallurgists pay particular attention to how different alloy and geometry combinations produce specific microstructures, strain rates, and mechanical properties under optimized conditions. Higher billet heating temperatures generally improve the tensile and yield strength of longitudinal weld seams, while extrusion speed has a more limited effect. However, extrusion speed remains a key variable to balance, as it directly affects both product quality and overall throughput.

Extrusion dies themselves are highly complex, involving geometry, thermal management, wear, service life, and performance differences between designs. Once the profile exits the press, it is quenched with air or water at controlled rates. Quenching is critical for achieving straightness and mechanical properties, and its effectiveness is strongly influenced by profile geometry and wall thickness. Thick walls are more difficult to cool, while internal cavities are harder for sprays to reach. To balance performance and productivity, quenching systems must adapt to different profile requirements. Key variables include inlet and outlet temperature, water temperature, water pressure, and the size, shape, and wall thickness of the extrudate. Nozzle design and spray angle also play important roles. Because quenching systems are difficult to observe directly, they are often described as “black boxes,” which makes data collection and analysis essential. After quenching, sensors typically measure the final profile temperature, but the reflective aluminum surface can affect accuracy. Some pyrometers address this with emissivity enhancers combined with software correction.

In later stages, pullers transfer the profiles to the run-out table for cutting before moving them to the cooling bed. Mechanical stretching introduces strain and dislocations, improving straightness and mechanical properties, with stretching force and speed being the most influential factors. Profiles are then cut to the required length by finishing saws, and cutting precision directly affects product quality. After cutting, profiles may enter a holding zone or a heat treatment area depending on property requirements. The common T6 temper demands strict heat treatment schedules, but because this adds both cost and time, manufacturers often reassess whether the treatment can be optimized or reduced while still meeting performance targets.

Overall productivity is also affected by downtime. Interruptions may occur during billet changes, removal of discard ends, die changes, maintenance, or purging of trapped gases. Reducing such dead-cycle time can significantly increase throughput.

The main outputs of extrusion include mechanical properties such as yield strength, ultimate tensile strength, elongation, and bending performance; dimensional and surface quality such as accuracy, straightness, and freedom from defects; and operational indicators such as scrap rate, scrap cost, and energy efficiency. These are the results that customers and manufacturers care about most.

When building machine learning models, data must be organized systematically. Inputs typically consist of alloy composition and process variables, while outputs include mechanical properties, quality indicators, and productivity. With robust datasets and algorithms, models can not only predict outcomes but also work in reverse. For example, if a customer requests higher-than-standard strength or elongation, the model can suggest the process conditions or alloy adjustments needed to achieve those targets.

Artificial intelligence is becoming increasingly important in manufacturing. For the aluminum extrusion industry, the challenge is to look beyond the hype and vague claims about AI and focus on the practical value of machine learning in process optimization, efficiency improvement, and better use of equipment. By combining deeper process understanding with data-driven decision-making, extrusion plants can increase efficiency, improve quality, and maintain a competitive edge.

Post time: Oct-01-2025