In the evolution of the aluminum processing industry, grain refinement technology has consistently played a central role in determining product quality and production efficiency. Since the establishment of the Tp-1 grain refiner evaluation method in 1987, the industry has long been plagued by persistent challenges—most notably, the instability of Al-Ti-B grain refiners and the high addition rates required to maintain refinement performance. It wasn’t until 2007 that a laboratory-initiated technological revolution fundamentally altered the trajectory of aluminum casting practices.

With its breakthrough Optifine super grain refiner, MQP achieved a quantum leap in refinement efficiency. Embracing the innovative concept of “less is more,” MQP offered global aluminum manufacturers a new path toward cost reduction and efficiency improvement. This article delves into the technological evolution, scientific principles, real-world applications, and future outlook of MQP’s revolutionary product, demonstrating how it has redefined industry standards.

I. Technological Breakthrough: From the Limitations of Opticast to the Birth of the Super Refiner

Every major scientific breakthrough begins with a critical reassessment of conventional wisdom. In 2007, Dr. Rein Vainik, reflecting on a decade of work with the Opticast process optimization technology for grain refinement, was confronted by a harsh reality: despite its promise, the process failed to overcome the persistent issue of unstable refinement performance at low addition levels of Al-Ti-B grain refiners.

Opticast was built on a seemingly perfect logic—adjusting refiner addition rates based on alloy types and scrap content to achieve precise low-dose control. However, user feedback consistently revealed that low addition rates of Al-Ti-B were sustainable only for brief periods. Once a wire spool change occurred, grain coarsening rapidly followed. This disconnect forced Dr. Vainik to revisit the core issue. The prevailing approach focused solely on alloy element variables, neglecting the variability of the grain refiner’s intrinsic refining power. In reality, the lack of quantification for both variables rendered so-called “precision control” nothing more than a laboratory illusion.

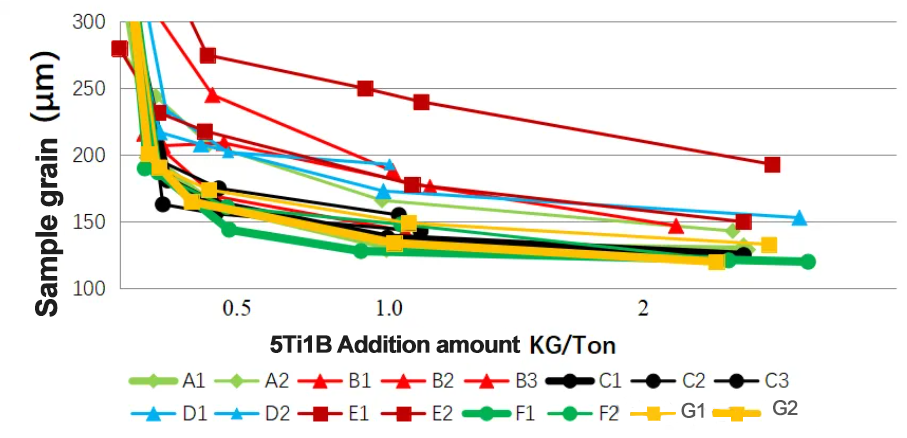

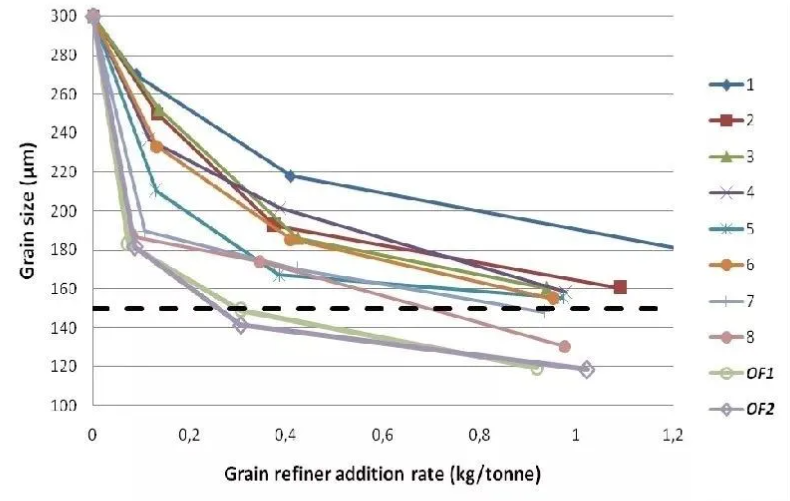

This paradigm shift laid the foundation for the super grain refiner’s invention. Shifting focus from the aluminum alloy to the Al-Ti-B grain refiner itself, Dr. Vainik conducted grain refinement curve tests on 16 different batches of 5Ti1B products using Opticast’s standardized testing protocol. Under identical chemical compositions and cooling conditions, only the batch varied. The results were shocking—even batches from the same manufacturer and grade exhibited enormous variation in refining power. The data exposed a long-overlooked industry pain point: the Tp-1 method, in use since 1987, failed to quantify the actual refining capacity of Al-Ti-B products.

Around the same time, MQP acquired Opticast AB. Founder John Courtenay, recognizing the market’s urgent needs, proposed a disruptive idea: to merge Opticast’s optimization approach with a “maximum refinement capacity” grain refiner. The focus would shift from controlling addition rates to enhancing refinement efficiency, addressing the root of the industry’s challenges. This shift led to a redefinition of what constituted a “high-performance grain refiner.” MQP named it the Optifine Super Grain Refiner and published its official definition in Light Metals Edited by TMS 2008—a grain refiner characterized by the highest nucleation potential.

The year 2007 is now widely recognized as the origin of the super grain refiner. It marked a turning point when the industry realized: the key to grain refinement is not “how much is added,” but “how strong the refiner is.” With this reconceptualization—from variability awareness to product definition—MQP opened a new era of high-efficiency production in aluminum processing.

The grain refining ability curve of ordinary aluminum titanium boron shows the dramatic fluctuation of aluminum titanium boron’s grain refining ability.

The refining ability curves No. 1-8 show the huge difference in refining ability of 8 batches of products from the same manufacturer.

OF-1 and OF-2 are the refining ability curves of Optifine super aluminum titanium boron, which show that the product has efficient and stable refining ability.

II. Scientific Foundation: Atomic-Level Differentiation

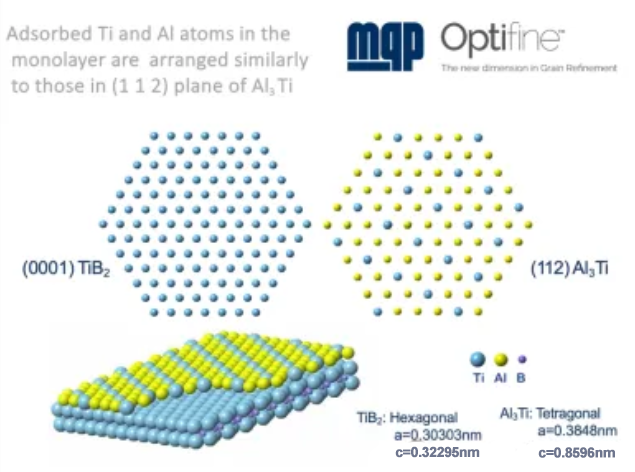

Lasting innovation requires a deep understanding of underlying scientific principles. The dramatic performance leap of the Optifine super grain refiner lies in its atomic-level elucidation of grain nucleation mechanisms. In 2021, MQP and Brunel University London jointly conducted the research project “The Nucleation Mechanism of α-Aluminum on TiB₂ Surfaces,” offering conclusive scientific evidence for the superior performance of the super grain refiner.

Using high-resolution transmission electron microscopy (HR-TEM), the research team made a groundbreaking discovery at the atomic scale: the presence of TiAl₃ atomic layers on the surface of TiB₂ particles. This microstructure difference revealed the fundamental secret behind variation in refinement efficiency. When comparing two samples—one with a relative refinement efficiency of 50% and the other with 123%—it was found that 7 out of 8 TiB₂ particles in the high-efficiency sample possessed a 2DC Ti₃Al interface layer, while only 1 out of 6 did so in the low-efficiency sample.

This finding overturned the traditional industry belief that TiB₂ particles alone were the core of grain nucleation. Instead, MQP’s research revealed that the quality and quantity of interfacial layers were the true determinants of nucleation probability. High-performance super grain refiners exhibit significantly superior atomic-level order and integrity on their TiB₂ particles compared to standard Al-Ti-B products. This microstructural advantage directly translates to macroscopic performance—more uniform and finer grains under the same addition rate, leading to superior product quality.

To quantify these differences, MQP developed a patented test method for Relative Refinement Efficiency (RRE), expressed as a percentage. It is calculated by comparing the number of grains formed per ppm B per mm³ of the test sample to a standard reference. When RRE exceeds 85%, the product is classified as an Optifine super Al-Ti-B product. This quantitative benchmark not only provides a scientific basis for performance assessment but also enables manufacturers to make informed decisions based on actual refining power.

From atomic-level discovery to quantitative metrics, MQP has laid a solid scientific foundation for the super grain refiner. Each upgrade in the Optifine series is supported by defined atomic mechanisms rather than empirical guesswork.

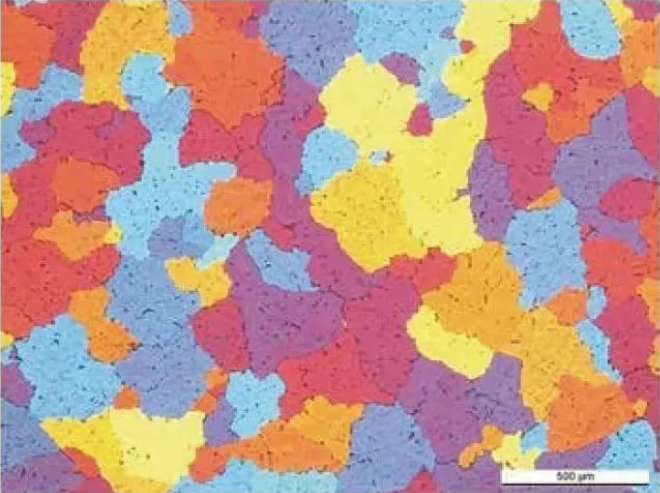

AA6060 alloy structure treated with Optifine grain refiner. Addition rate is 0.16kg/t, ASTM=2.4

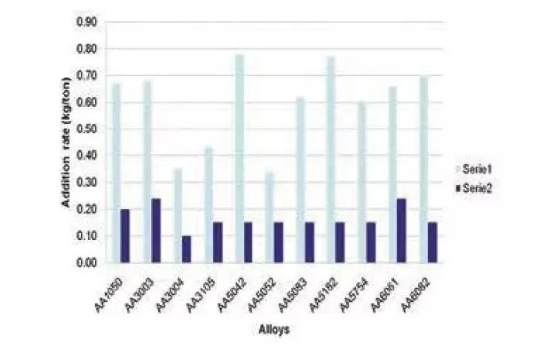

The amount of Optifine (dark blue) grain refiner versus conventional TiBAI (light blue) grain refiner required for an aluminum alloy.

III. Product Iteration: Evolving Toward Peak Performance

The vitality of any technology lies in continuous innovation. Since its debut, MQP has leveraged its strong R&D capabilities to iteratively enhance the Optifine product line, pushing boundaries in both efficiency and stability. From the original Optifine31 100 to Optifine51 100 and now the high-performance Optifine51 125, each generation has achieved significant increases in RRE, directly translating into reduced addition rates—embodying MQP’s philosophy of “quality over quantity.”

The initial release, Optifine31 100, immediately showcased its disruptive potential. With RRE levels far surpassing traditional products, it maintained grain refinement while cutting addition rates by over 50% compared to industry norms. This success validated the super grain refiner concept and laid the groundwork for future improvements.

As industry demands escalated, MQP introduced Optifine51 100, which improved the uniformity of TiB₂ particle distribution while maintaining stability. It delivered approximately 20% higher RRE than the original, allowing an additional 15–20% reduction in addition rates—ideal for aerospace and premium construction materials where quality and consistency are critical.

At the peak of the current lineup is Optifine51 125, achieving an RRE of 125%. This is attributed to a significantly higher formation rate of the 2DC Ti₃Al interface layer on TiB₂ particles. Experimental data confirm that the nucleation probability of this product is 2–3 times higher than conventional alternatives, maintaining stable performance even in complex alloy systems or high-recycled-content melts. For manufacturers of high-value aluminum products, Optifine51 125 cuts refiner costs by over 70% and dramatically reduces scrap caused by coarse grains.

In 2025, MQP announced its Optifine502 Clean product plan, extending innovation into new niches. Targeting surface defects, this variant precisely controls TiB₂ particle quantities to minimize particle agglomeration while preserving refinement efficiency. It is poised to serve applications such as ultra-smooth aluminum foils and mirror-finish panels, solving yet another long-standing industry challenge.

From enhancing efficiency to optimizing surface quality, MQP’s product evolution clearly follows one core logic: science-driven, customer-centric innovation that reshapes the full value chain of aluminum processing.

IV. Global Validation: From Early Adoption to Industry Standard

A new technology’s value is ultimately proven through widespread adoption. In 2008, when South Africa’s Hulamin became the first company to trial the Optifine super grain refiner, few anticipated how significant that decision would become. Applying it to AA1050 alloy production, Hulamin achieved striking results—reducing refiner addition from 0.67 kg/ton to 0.2 kg/ton, a 70% savings. This not only slashed costs but also validated the product’s real-world reliability.

Hulamin’s success opened the global market for Optifine. Leading aluminum producers soon followed. Sapa (later acquired by Hydro) rolled out Optifine across its European plants, reducing refiner usage by an average of 65% across multiple alloys. Aleris (now Novelis) applied it in automotive sheet production, enhancing mechanical properties while reducing stamping rejects. Alcoa incorporated it into aerospace-grade aluminum production, achieving precise composition control through a combination of Optifine and Opticast.

Entering China in 2018, MQP quickly gained traction in the country’s high-end aluminum sector. As the world’s largest aluminum producer and consumer, China urgently needs to reduce costs and boost quality. The introduction of Optifine aligned perfectly with the country’s pivot to high-end manufacturing.

One prominent example is a Chinese aluminum foil company producing high-precision foils, where traditional refiners caused issues like pinholes and foil breaks due to batch variability. After switching to Optifine51 100, addition rates dropped from 0.5 kg/ton to 0.15 kg/ton, and pinhole defects fell by 80%. The company estimates annual savings of over RMB 20 million due to reduced scrap and lower refiner costs.

In the architectural profiles sector, a major Chinese producer used Optifine to address poor coating adhesion caused by coarse grains. Average grain size was reduced from 150 μm to under 50 μm, increasing coating adhesion by 30% and raising product yield from 85% to 98%. With a cost saving of RMB 120 per ton, the firm saves over RMB 12 million annually at a 100,000-ton output.

These global case studies underscore one conclusion: MQP’s super grain refiner is more than a laboratory innovation—it is a mature industrial solution proven across continents. From South Africa to Europe, North America to China, the Optifine series has become a staple for industry giants like Sapa, Novelis, and Hydro, establishing a new standard: focus on refinement efficiency, not just dosage.

As of 2024, over 200 aluminum processors worldwide have adopted MQP’s technology, collectively saving more than 100,000 tons of Al-Ti-B and cutting carbon emissions by approximately 500,000 tons. These figures reflect not just economic benefits but also substantial contributions to sustainable manufacturing.

V. Looking Ahead: From Technical Innovation to Ecosystem Transformation

When a technology transcends performance limits, its impact often extends beyond the product itself—reshaping the entire industry ecosystem. The rise of MQP’s super grain refiners exemplifies this principle. As the Optifine series continues to evolve and diversify, its transformative influence is expanding from production processes to upstream and downstream segments of the value chain.

Technically, MQP’s research partnerships—such as the one with Brunel University—have set a benchmark for industry–academia collaboration. Their work has created a full-cycle model of “basic research–application development–industrialization.” As material science and atomic-scale imaging technologies advance, future breakthroughs in nano-interface control and predictive intelligence may further enhance precision and adaptability.

From an application standpoint, super grain refiners will increasingly serve niche markets. The Optifine502 Clean product points toward a trend of customization—tailoring solutions to specific product types (foil, sheet, extrusions) and process conditions (twin-roll casting, semi-continuous casting). Custom refiners will help manufacturers maximize economic returns and foster differentiated, high-value competition across the sector.

In an era where green manufacturing is a global imperative, the environmental benefits of MQP’s technology are especially compelling. By reducing Al-Ti-B consumption, super grain refiners lower upstream energy use and emissions. At the same time, improved product quality means less waste. As carbon footprint tracking becomes more prevalent, using super grain refiners may become a prerequisite for certifications and market access—accelerating the industry’s low-carbon transition.

For China, MQP’s technology offers critical support for upgrading the domestic aluminum industry. Despite being the largest producer globally, China still has room to grow in high-end segments like aerospace and automotive. With enhanced consistency and cost savings, Optifine helps Chinese companies overcome technical barriers and improve global competitiveness. In turn, collaboration with MQP could inspire localized innovation, fostering a virtuous cycle of “introduction–absorption–reinvention.”

Post time: Jul-26-2025