Compared with the more common 6xxx alloys, the basic differences in extruding higher-strength 2xxx and 7xxx aluminum alloys are as follows:

-They require higher extrusion pressure.

-Extrusion speed is slower.

-They require separate furnace solution heat treatment.

-Special equipment is needed to extrude hollow shapes.

-They are highly susceptible to peripheral coarse-grain recrystallization.

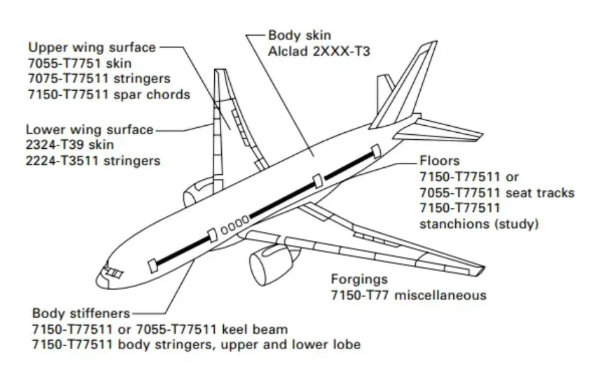

Typical major elements of 2xxx alloys are shown in Figure 1. The 2xxx series alloys include several groups. The Al-Cu group contains binary alloys (e.g., 2219 with 6% Cu). Al-Cu-Mg alloys (e.g., 2024 and 2014) are the most commonly used 2xxx series extrusions for aircraft structures. They evolved from the 2017 alloy discovered by Wilm in 1911. These alloys possess medium to high strength with good ductility and toughness. 2024 and 2014 alloys are mainly used as structural components on the lower wing surface, where tensile, fatigue, and stress corrosion conditions make many higher-strength 7xxx alloys unacceptable. Variants of these alloys, such as 2124 and 2224, offer improved properties—particularly fracture toughness—through a combination of purity control, microstructural development, and temper optimization.

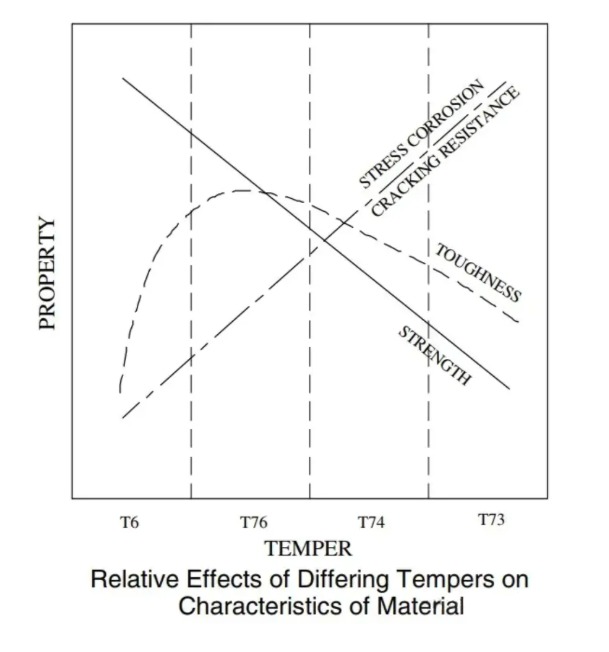

Typical major elements of 7xxx alloys are shown in Figure 2. Alloys in the 7xxx series are divided into two main categories. The Al-Zn-Mg medium/high-strength alloys exhibit significantly better extrudability because of their lower flow stress, and most can be air-quenched on the press. Al-Zn-Mg alloys such as 7003, 7004, 7005, and 7020 can be extruded using conventional hollow-die technology and are within the capability of most extrusion facilities. High-strength Al-Zn-Mg-Cu alloys used in aerospace applications require separate solution heat treatment, higher extrusion pressures, and cannot be extruded into hollow shapes unless a specialized seamless extrusion press is used. The cornerstone alloy of the Al-Zn-Mg-Cu group, shown in Figure 2, is 7075. Higher-purity variants such as 7175, 7475, and 7150 provide increased fracture toughness, though with some loss in strength. This improvement is achieved through the application of new overaged T7x tempers.

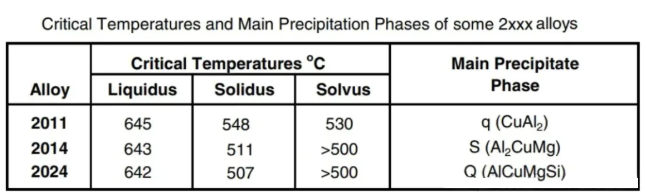

Critical temperatures and main precipitate phases of several 2xxx alloys are shown in Figure 4. Because many 2xxx alloys have a long solidification range (the difference between liquidus and solidus temperatures), solidification proceeds slowly, forming coarse dendritic structures. Microsegregation tends to be significant, and dissolution during homogenization is slow—especially under commercial conditions where temperatures cannot approach the liquidus. The long solidification range also affects the inverse segregation depth on the billet surface, often requiring longer extrusion discard lengths (up to 12%).

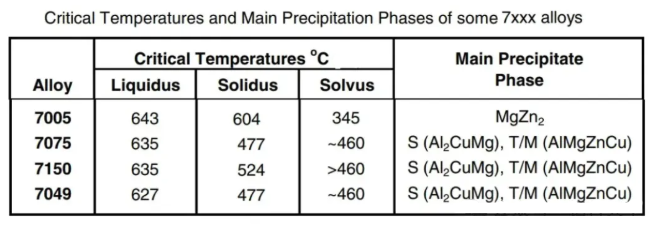

Common 7xxx alloys consist of two basic groups: medium to high-strength Al-Zn-Mg alloys and high-strength Al-Zn-Mg-Cu alloys. Their critical temperatures and major precipitation stages are shown in Figure 5. The long solidification range typical of Al-Zn-Mg-Cu alloys causes microsegregation problems similar to those found in the 2xxx series.

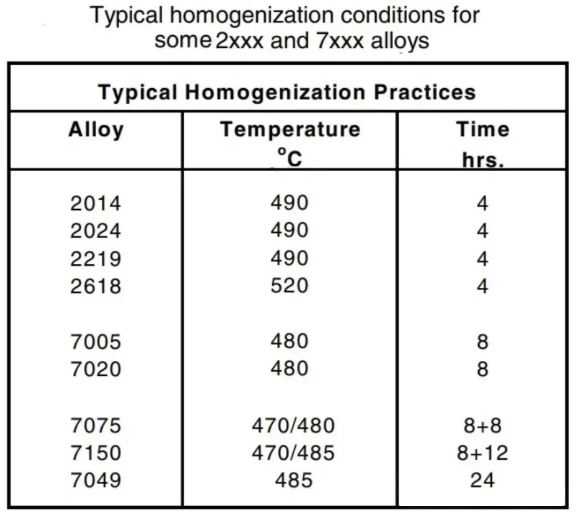

Typical billet homogenization practices for 2xxx and 7xxx alloy billets are shown in the figure below.

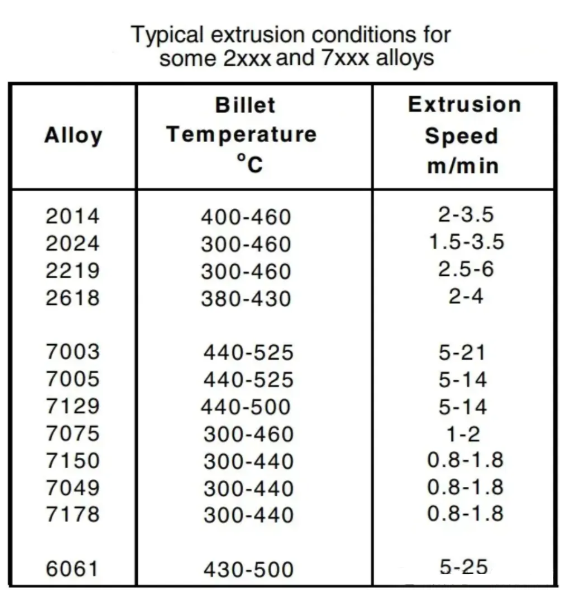

Typical extrusion conditions for some common 2000 and 7000 alloys are shown in Figure 7. 2000 and 7000 alloys are generally prone to recrystallization. Recrystallization is a complex interaction between billet composition, metallurgy, extrusion conditions, and critical temperatures (e.g., solution, solidus, and recrystallization temperatures).

Al-Zn-Mg alloys, such as 7005, can be air-cooled on the press and extruded under conditions where the die exit temperature is sufficiently above the solution temperature, enabling effective solution heat treatment during passage through cooling fans. In addition, the extrusion exit temperature is usually lower than the recrystallization temperature for these alloys, so recrystallization does not occur.

In contrast, high-strength Al-Zn-Mg-Cu alloys behave quite differently. For each alloy, the solution temperature is higher and closer to the solidus temperature, eliminating the possibility of effective solution heat treatment through thermal forming. Therefore, separate furnace solution heat treatment is required.

For 2xxx series alloys, the gap between the solution and solidus temperatures is very narrow, sometimes less than 10°C. Consequently, peripheral coarse-grain recrystallization is more common and more severe during extrusion of 2xxx alloys.

The figure below highlights how much slower the extrusion speeds of 2xxx and 7xxx series alloys are compared with the more common 6061 alloy. Lower solidus temperatures during homogenization and incomplete dissolution of low-melting phases increase the risk of hot shortness, speed cracking, or tearing, which limits higher extrusion speeds. In terms of extrusion pressure and speed, Al-Zn-Mg alloys of the 7xxx series are easier to extrude than the higher-strength Al-Zn-Mg-Cu alloys. Typically, these alloys are extruded at exit temperatures not exceeding 530°C.

Extrusion presses capable of extruding higher-strength 2xxx and 7xxx alloys can supply products to specialized markets such as aerospace, where prices are significantly higher than those for more common 6xxx series alloys. However, extruders must be familiar with the many challenges associated with extruding and processing such high-strength alloys.

Post time: Nov-08-2025